UW NNCI Site - WNF Lab Tool List

Device and Structure Characterization

| ||||||||||||||||||||||

Description

This is a contact profilometer capable of measuring step heights that range from tens of nanometers to one millimeter. It can also measure surface roughness and film stress. It can accommodate 100mm, 125 mm, and 150 mm wafers as well as smaller chips. It is capable of automated measurements with step detection. The stylus has a radius of 2 um and a cone angle of 60 degrees.

Details

(none given)

Materials Restrictions

(none)

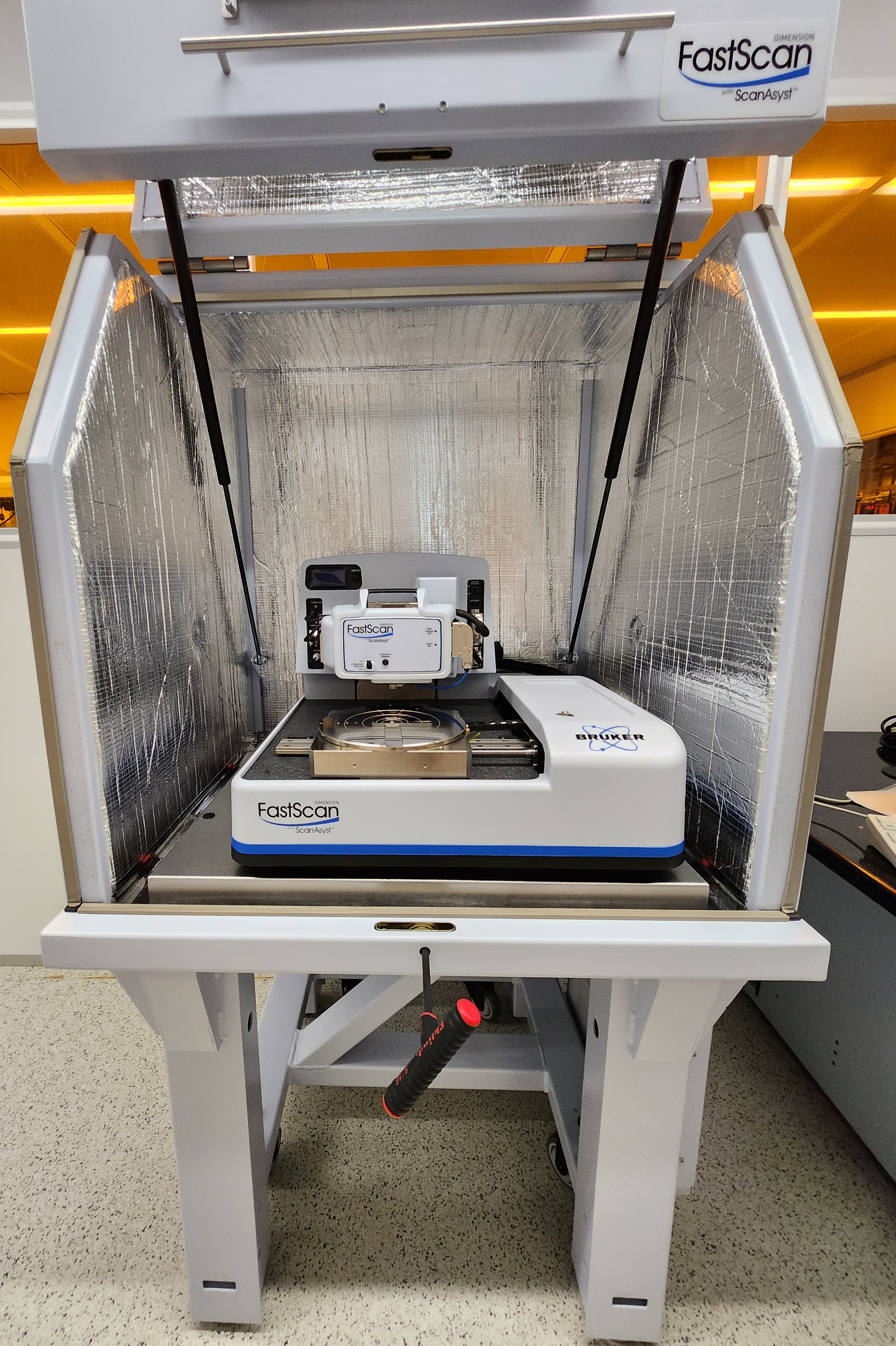

Bruker Dimension FastScan AFM |

| |

|---|---|---|

| Coral ID: | WNF--AFM--Bruker-Dimension-FastScan | |

| Manufacturer: | Bruker | |

| Model: | Dimension FastScan | |

| Lab: | WNF | |

| Area: | Device and Structure Characterization | |

| Manual: | Bruker FastScan Atomic Force Microscope SOP.pdf | |

| UW Academic Rate: | $55/hr | |

| Industrial Rate: | $165/hr | |

| Outside Academic Rate: | $55/hr | |

Description

This is an atomic force microscope is capable of high resolution imaging of small step heights and material surfaces. The tool can also measure magnetic or atomic forces. The tool can accommodate samples up to a 200mm wafer.

Details

Vertical scan height of 4.47um

Nanometer scale resolution

Materials Restrictions

Samples must be clean and dry. Features should be less than 4.4um tall

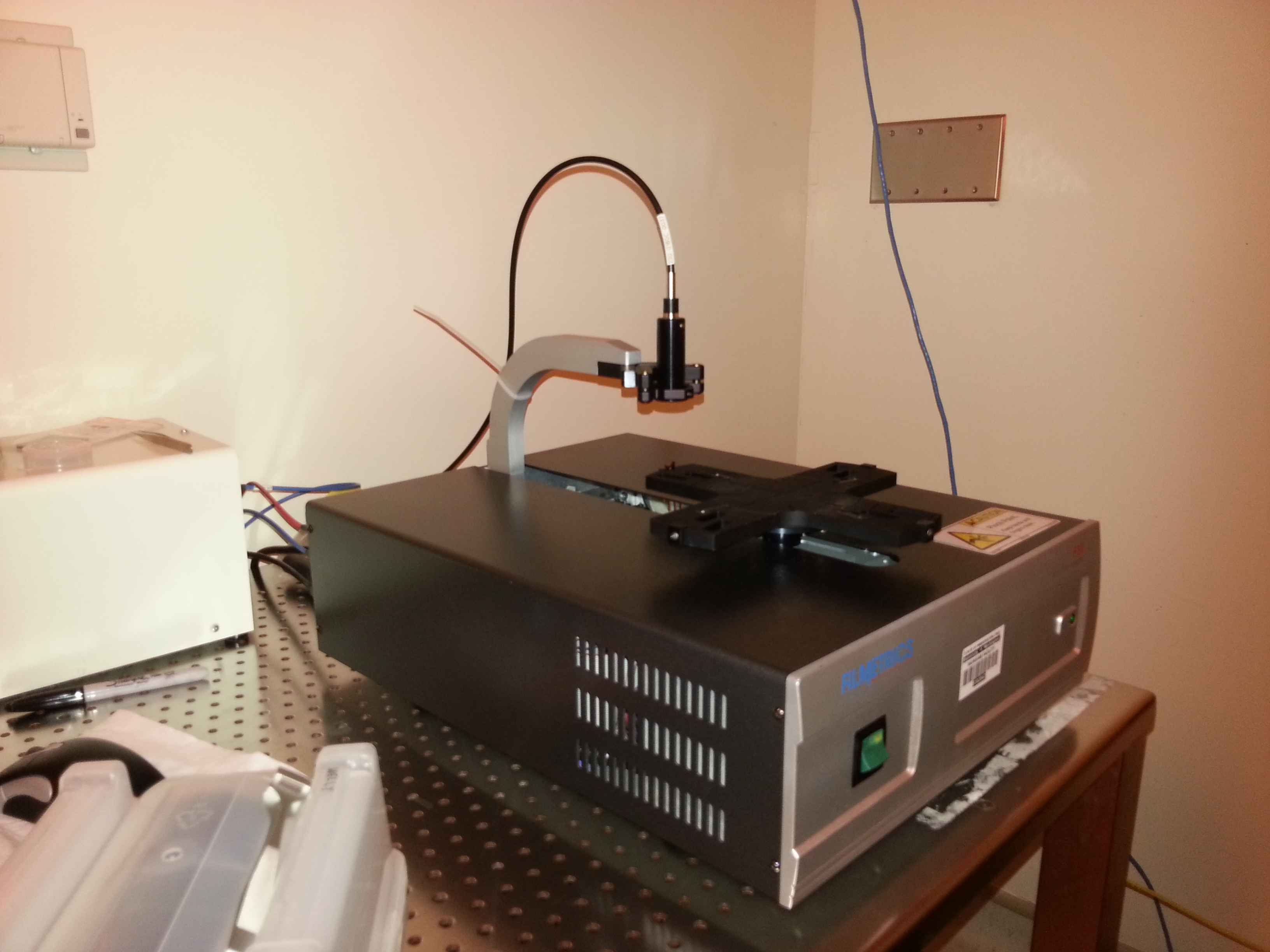

Filmetrics F50 Thin Film Reflectometer |

| |

|---|---|---|

| Coral ID: | WNF--Reflectometer--Filmetrics-F50 | |

| Manufacturer: | Filmetrics | |

| Model: | F50 | |

| Lab: | WNF | |

| Area: | Device and Structure Characterization | |

| Manual: | FilmetricsUserInstructions_V1.0.pdf | |

| UW Academic Rate: | $11/hr | |

| Industrial Rate: | $33/hr | |

| Outside Academic Rate: | $11/hr | |

Description

Optical measurement of thin film layers on various substrates. Uses spectral reflectance to determine film thickness, refractive index, and extinction coefficient by scanning wavelengths from 200 to 1700 nm. Substrates up to 150 mm can be mapped automatically.

Details

(none given)

Materials Restrictions

(none)

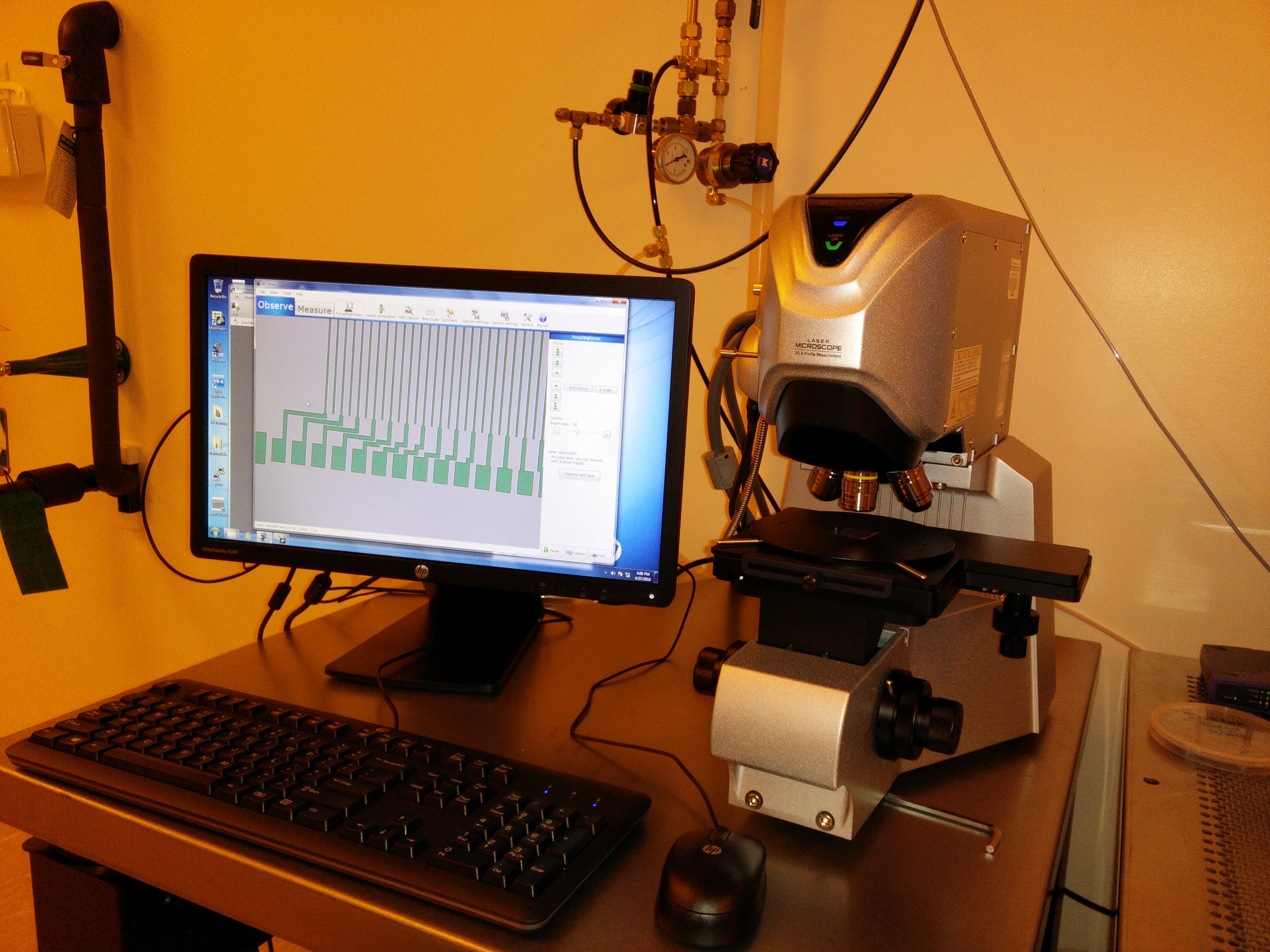

Keyence Laser Scanning Confocal Microscope |

| |

|---|---|---|

| Coral ID: | WNF--Confocal-Microscope--Keyence-VK-X150K | |

| Manufacturer: | Keyence | |

| Model: | VK-X150K | |

| Lab: | WNF | |

| Area: | Device and Structure Characterization | |

| Manual: | Keyence_SOP1_1.pdf | |

| UW Academic Rate: | $11/hr | |

| Industrial Rate: | $33/hr | |

| Outside Academic Rate: | $11/hr | |

Description

This laser scanning confocal microscope obtains 3D measurements from a wafer surface for measurement of both step heights and lateral dimensions. This model uses a red (658 nm) laser. The step height measurement has a resolution of 5 nm with a minimum step height of 50 nm. Lateral measurements have a resolution of 250 nm.

Details

(none given)

Materials Restrictions

(none)

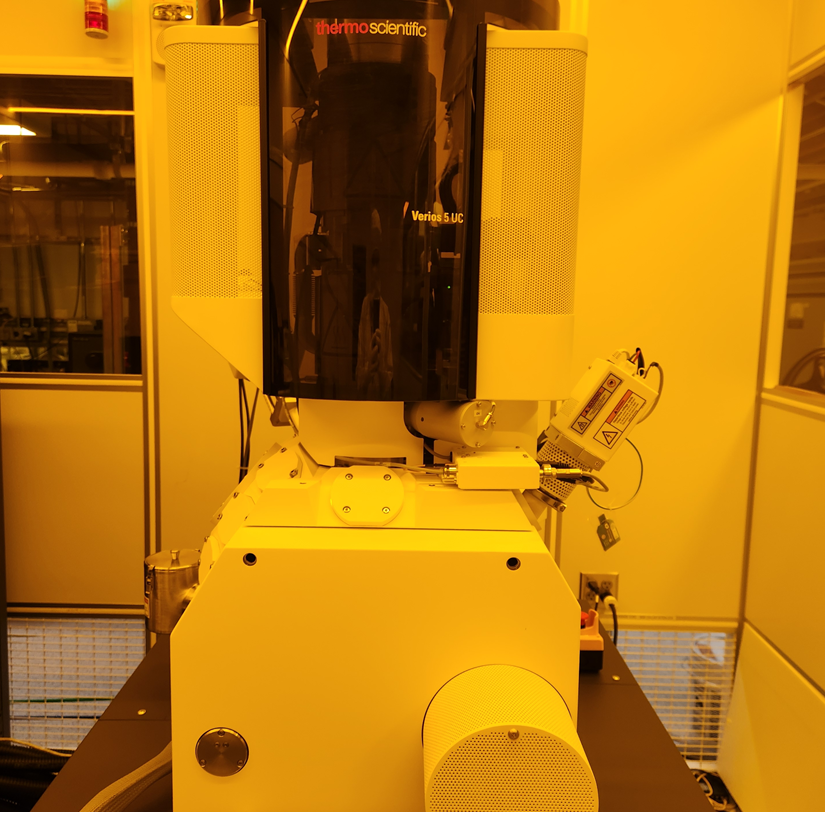

SEM-FEI |

| |

|---|---|---|

| Coral ID: | WNF--SEM--FEI-Verios | |

| Manufacturer: | FEI | |

| Model: | Verios 5 | |

| Lab: | WNF | |

| Area: | Device and Structure Characterization | |

| Manual: | Verios_SOP.pdf | |

| UW Academic Rate: | $77/hr | |

| Industrial Rate: | $231/hr | |

| Outside Academic Rate: | $77/hr | |

Description

Very high resolution, field emission scanning electron microscope. This microscope has multiple scanning modes as well as a multitude of detectors for both secondary (topographical) and backscattered (compositional) electrons. The tool is also equipped with an EDS detector for compositional analysis

Details

A high vacuum chamber allows for high-resolution imaging. The Elstar column allows for quality imaging at a variety of voltages and currents, enabling imaging of insulating samples without the need for coating. The tool also has a variety of holder to mount substrates from chips up to 150mm wafers. Tilt angle range depends on substrate size and working distance.

Materials Restrictions

Clean, low-outgassing substrates only. No magnetic samples.

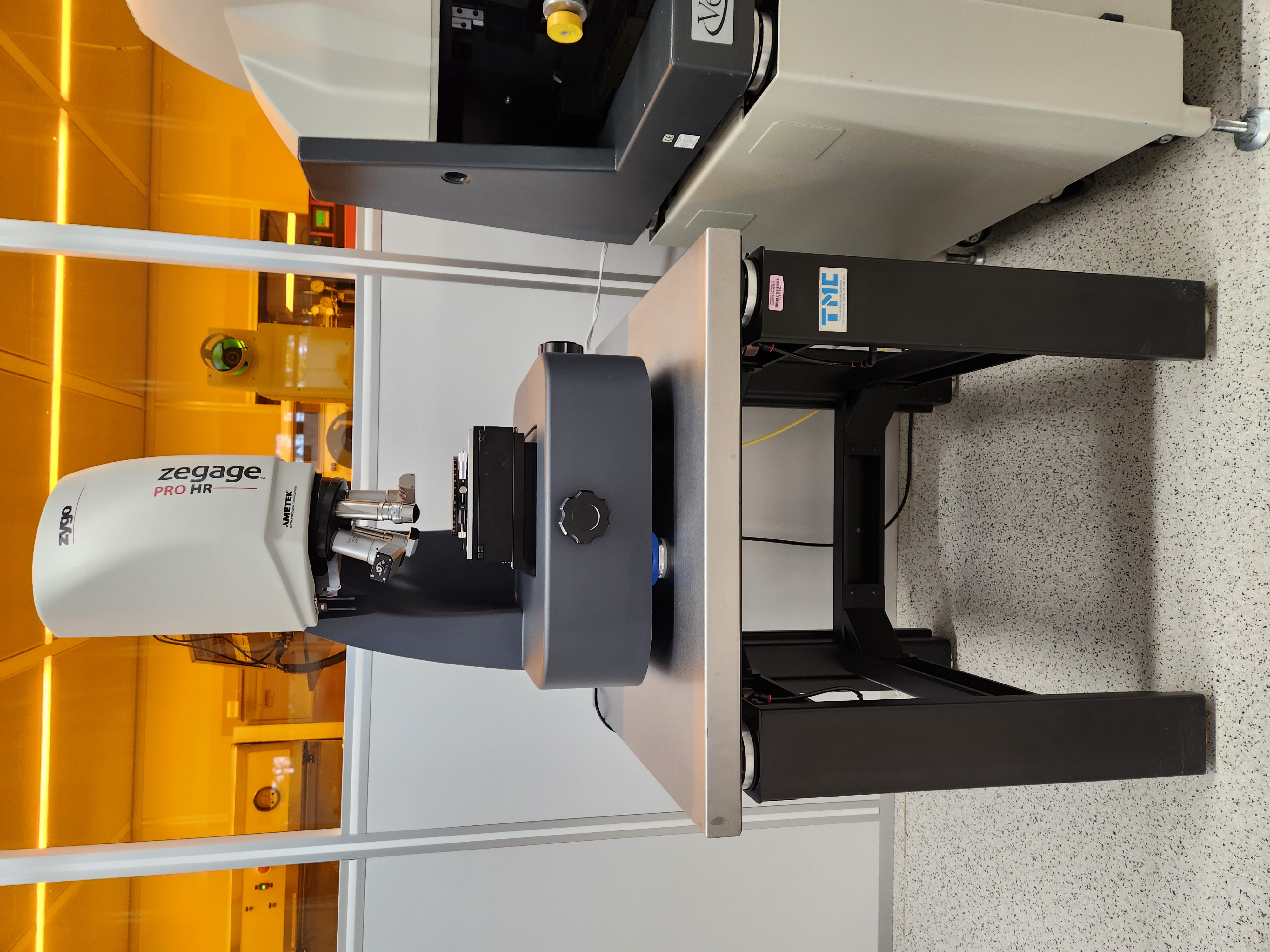

Zygo ZeGage Pro HR |

| |

|---|---|---|

| Coral ID: | WNF--Profilometer--Zygo-ZeGage-Pro-HR | |

| Manufacturer: | Zygo | |

| Model: | ZeGage Pro HR | |

| Lab: | WNF | |

| Area: | Device and Structure Characterization | |

| Manual: | SOP Draft Zygo.pdf | |

| UW Academic Rate: | $55/hr | |

| Industrial Rate: | $165/hr | |

| Outside Academic Rate: | $55/hr | |

Description

The ZeGage Pro HR is a high resolution 3D optical profilometer using white light interferometry to achieve sub-nanometer resolution.

Details

Specifications:

Vertical scan range: 20 mm

Surface topography repeatability: ≤ 0.15 nm

Repeatability of RMS: 0.01 nm

Step height accuracy: ≤ 3%

Features include:

- Objectives:

- Measurement array up to 1600x1200

- Motorized stage and automation with 100 mm travel

Materials Restrictions

Samples must be clean and dry. No residue should be left behind on the stage.

Dry Etch

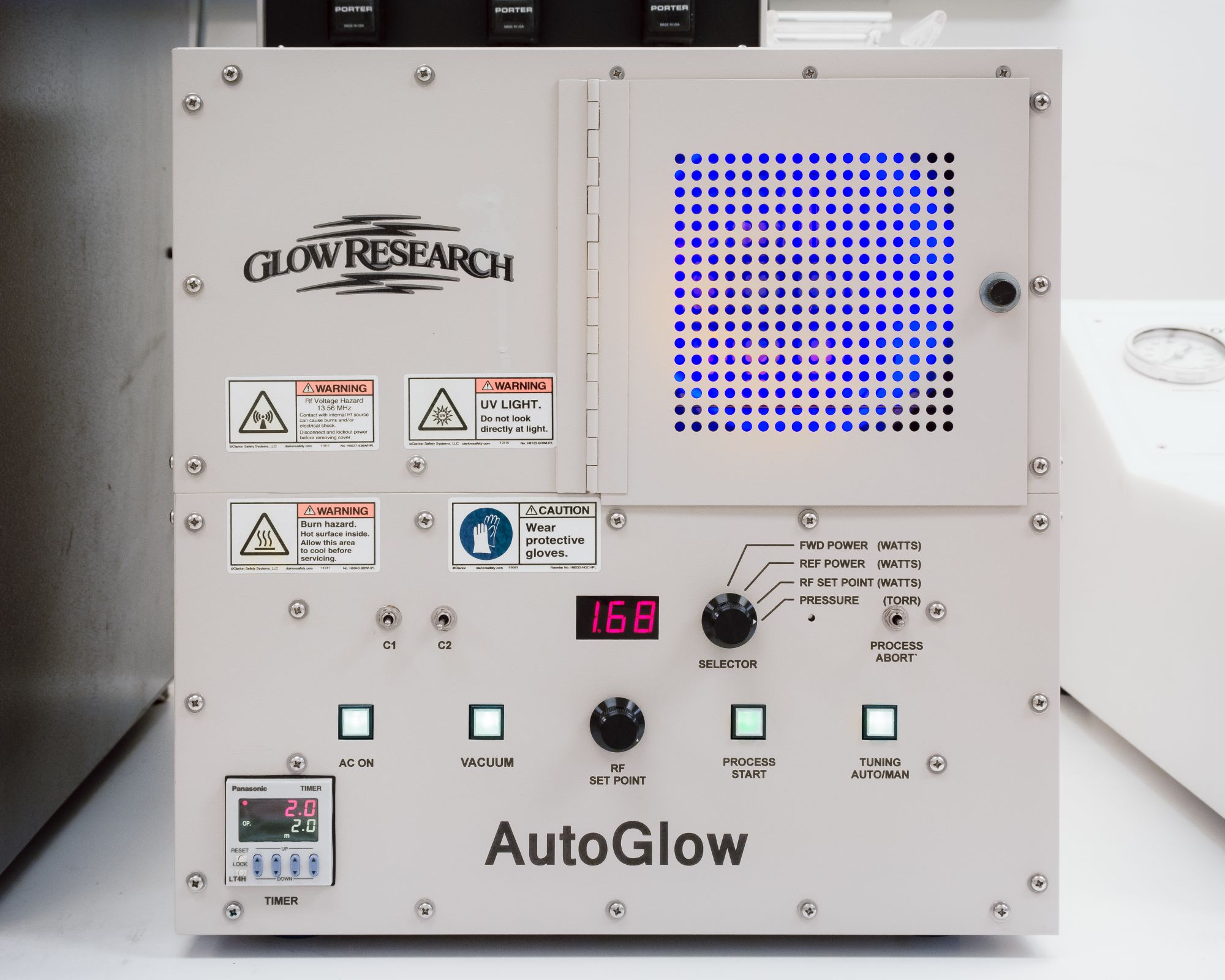

Barrel Asher |

| |

|---|---|---|

| Coral ID: | WNF--Asher--BarrelEtch | |

| Manufacturer: | Glow Research | |

| Model: | AutoGlow | |

| Lab: | WNF | |

| Area: | Dry Etch | |

| Manual: | SOP_Barrel_Asher_v2d.pdf | |

| UW Academic Rate: | $55/hr | |

| Industrial Rate: | $165/hr | |

| Outside Academic Rate: | $55/hr | |

Description

Barrel asher used to strip resist or other organic films, descum patterned resist, or clean surfaces of residual organics using an isotropic oxygen plasma.

Details

Accomodates substrate from chips up to 100mm diameter wafers.

Materials Restrictions

Allowed etch target materials: Photoresist, e-beam resist, organic contaminants, other polymers (No SU8.) No high-vapor-pressure materials. Please contact tool owner to discuss materials not included on this list.

ICP01 Special Materials |

| |

|---|---|---|

| Coral ID: | WNF--DRIE1--Oxford | |

| Manufacturer: | Oxford Instruments | |

| Model: | ICP 380 | |

| Lab: | WNF | |

| Area: | Dry Etch | |

| Manual: | ICP1-SpecialMaterial-Oxford_SOPv7_07232024.pdf | |

| UW Academic Rate: | $77/hr | |

| Industrial Rate: | $231/hr | |

| Outside Academic Rate: | $77/hr | |

Description

ICP Etch system for etching Lithium Niobate, 2-D materials (WSe2, BN, MoS2...) and other special materials.

Details

100mm wafers - chips must use a 100mm carrier wafer with die attach via Fomblin or Stantovac vacuum oils. Available process gases: SF6 (0-100sccm), O2 (0-100sccm), C4F8 (0-100sccm), Ar (0-100sccm), H2 (0-50sccm), and CH4 (0-100sccm). NOTE: Tool configuration alternates between Lithium-containing-compound-etching, Magnesium-containing-compound-etching, and Non-Lithium/Magnesium-containing-compound-etching. Each configuration has a dedicated quartz clamp ring with extensive manual and plasma chamber cleaning occurring during the re-configuration. Generally, the configuration schedule alternates on a weekly basis; however, this regime may deviate from this depending on user requirements. Please see tool owner for details. Current configuration can be found in Coral comments for this tool (search both 'unresolved' and 'resolved' comments).

Materials Restrictions

100mm wafers or dies/chips attached to 100mm carrier wafer. Allowed etch target materials: Silicon, Silicon Oxide, Silicon Nitride, Lithium Niobate, 2D materials, PMDS, Polyimide, Parylene, Graphene, Niobium, some refractory metals. Allowed mask materials: Photoresist, E-Beam Resist, SiO2, Silicon Nitride, Alumina, some metal masks. Please see tool owner to discuss and gain permission for other hard mask materials, including metal masks. No exposed Copper, Gold, nor Silver. No high-vapor-pressure materials. Please contact the tool owner to discuss materials not included on this list.

ICP02-Fluorine |

| |

|---|---|---|

| Coral ID: | WNF--ICP--Oxford-Fluorine | |

| Manufacturer: | Oxford | |

| Model: | PlasmaLab 100, ICP-180 | |

| Lab: | WNF | |

| Area: | Dry Etch | |

| Manual: | ICP2-F-Oxford_UserSOP_v10_Feb2026_new software.pdf | |

| UW Academic Rate: | $77/hr | |

| Industrial Rate: | $231/hr | |

| Outside Academic Rate: | $77/hr | |

Description

Plasma tool capable of highly anisotropic etching using fluorine-based etch chemistries. Additionally, isotropic etching is available via ICP-only configuration. Load-locked for rapid load/unload and good process consistency. Wafer stage is temperature controlled via chilled nitrogen gas - upon request, additional LN2-cooling is available for cryo-etching. NOTE: New chamber cleaning policy: all chamber cleaning must be done with the system enabled and, at intervals of no more than 15 minutes, users must confirm the clean process continues to run to completion without error. The tool may be disabled only if there is less than 15 minutes left on the clean.

Details

Process gases: C4F8, CHF3, N2, O2, Ar, and SF6. 100mm wafers only. Smaller sizes can be accomodated using a 100mm silicon wafer as a carrier wafer.

Materials Restrictions

Allowed etch target materials: Silicon, Silicon Dioxide (see below), Silicon Nitride, some refractory metals including Tungsten and Molybdenum, SiC, Polyimide, Parylene, Graphene. Allowed mask materials: Photoresist, E-Beam Resist, SiO2, Silicon Nitride, Alumina. (Metal masks are not allowed.) No dirty glass can be etched (<99% SiO2), ie no pyrex, no borosilicate, no soda-lime. No exposed metal including copper, gold, and silver. Note: SiO2 (quartz and fused silica) are limited to 4um total etch depth. No high-vapor-pressure materials. Please contact tool owner to discuss materials not included on this list.

ICP03-Chlorine | ||

|---|---|---|

| Coral ID: | WNF--ICP--Oxford-Chlorine | |

| Manufacturer: | Oxford | |

| Model: | PlasmaLab 100, ICP-180 | |

| Lab: | WNF | |

| Area: | Dry Etch | |

| Manual: | ICP3-Cl-Oxford_UserManual_v6B.pdf | |

| UW Academic Rate: | $77/hr | |

| Industrial Rate: | $231/hr | |

| Outside Academic Rate: | $77/hr | |

Description

Highly anisotropic Inductively Coupled Plasma (ICP) etching using chlorine-based etch chemistries for etching Silicon and III-V semiconductors. Atomic Layer Etch (ALE) process allows for time-multiplexed etching to remove etch damage and achieve low etch rates. Load-locked for rapid load/unload and high process consistency. See tool owner for specific material restrictions.

Details

Process gases: BCl3, Cl2, H2, N2, O2, and Ar. A heated stage allows etching at substrates temperatures up to 400 C. 100mm wafers only. Smaller sizes can be accommodated using a 100mm silicon wafer as a carrier wafer (Users must supply their own carrier wafer - do not use the system shield wafer as a carrier).

Materials Restrictions

Allowed etch target materials: Silicon, Silicon Dioxide (see below), Silicon Nitride, GaAs, GaP, GaN, AlN, InP, Al, Cr, Ti. Contact tool owner for other III-V and II-VI materials. Allowed mask materials: Photoresist, E-Beam Resist, SiO2, Silicon Nitride, Alumina. Metal masks not allowed. No exposed noble metals including copper. Do not etch quartz nor fused silica. Note: Certain III-V compounds require elevated chuck temperatures - see tool owner. No high-vapor-pressure materials. Please contact tool owner to discuss materials not included on this list.

Reactive Ion Etcher 1 |

| |

|---|---|---|

| Coral ID: | WNF--RIE1--Vision | |

| Manufacturer: | Vision | |

| Model: | Vision 320 RIE Mark II | |

| Lab: | WNF | |

| Area: | Dry Etch | |

| Manual: | RIE1-Cortex_UserManual_v6.2.pdf | |

| UW Academic Rate: | $77/hr | |

| Industrial Rate: | $231/hr | |

| Outside Academic Rate: | $77/hr | |

Description

A parallel-plate Reactive Ion Etch (RIE) system. Open load for flexible substrate handling. Etch gases are: Ar, CF4, CHF3, O2, and SF6.

Details

Open load with ~12-inch platen allowing multiple substrates and substrate sizes.

Materials Restrictions

Allowed Etch target materials: silicon, silicon nitride, silicon oxide, PMDS, Polyimide, Parylene, Graphene, photoresist. Allowed mask materials: photoresist, ebeam-resist, silicon oxide, silicon nitride, alumina. No metal masks are allowed. No Exposed metal (including copper, gold, and silver) nor dirty glasses (<99% SiO2). Please contact the tool owner to discuss materials not included on this list. No high-vapor-pressure materials.

Reactive Ion Etcher 2 |

| |

|---|---|---|

| Coral ID: | WNF--RIE2--Vision | |

| Manufacturer: | Advanced Vacuum | |

| Model: | Vision 320 MkII | |

| Lab: | WNF | |

| Area: | Dry Etch | |

| Manual: | RIE2-Cortex_UserManual_v4.1.pdf | |

| UW Academic Rate: | $77/hr | |

| Industrial Rate: | $231/hr | |

| Outside Academic Rate: | $77/hr | |

Description

A parallel-plate Reactive Ion Etch (RIE) system. Open load for flexible substrate handling. Etch gases are: Ar, CF4, CHF3, N2, O2, and SF6. This the designated clean RIE tool - Allowed materials are strictly enforced.

Details

Open load system with 12-inch platen allowing multiple substrates and substrate sizes.

Materials Restrictions

Allowed Etch target materials: silicon, silicon nitride, silicon oxide, PMDS, Polyimide, Parylene, Graphene, photoresist. Allowed mask materials: photoresist, ebeam-resist, silicon oxide, silicon nitride, alumina. No metal masks are allowed. No Exposed metal (including copper, gold, and silver) nor dirty glasses (<99% SiO2). Please contact the tool owner to discuss materials not included on this list. No high-vapor-pressure materials.

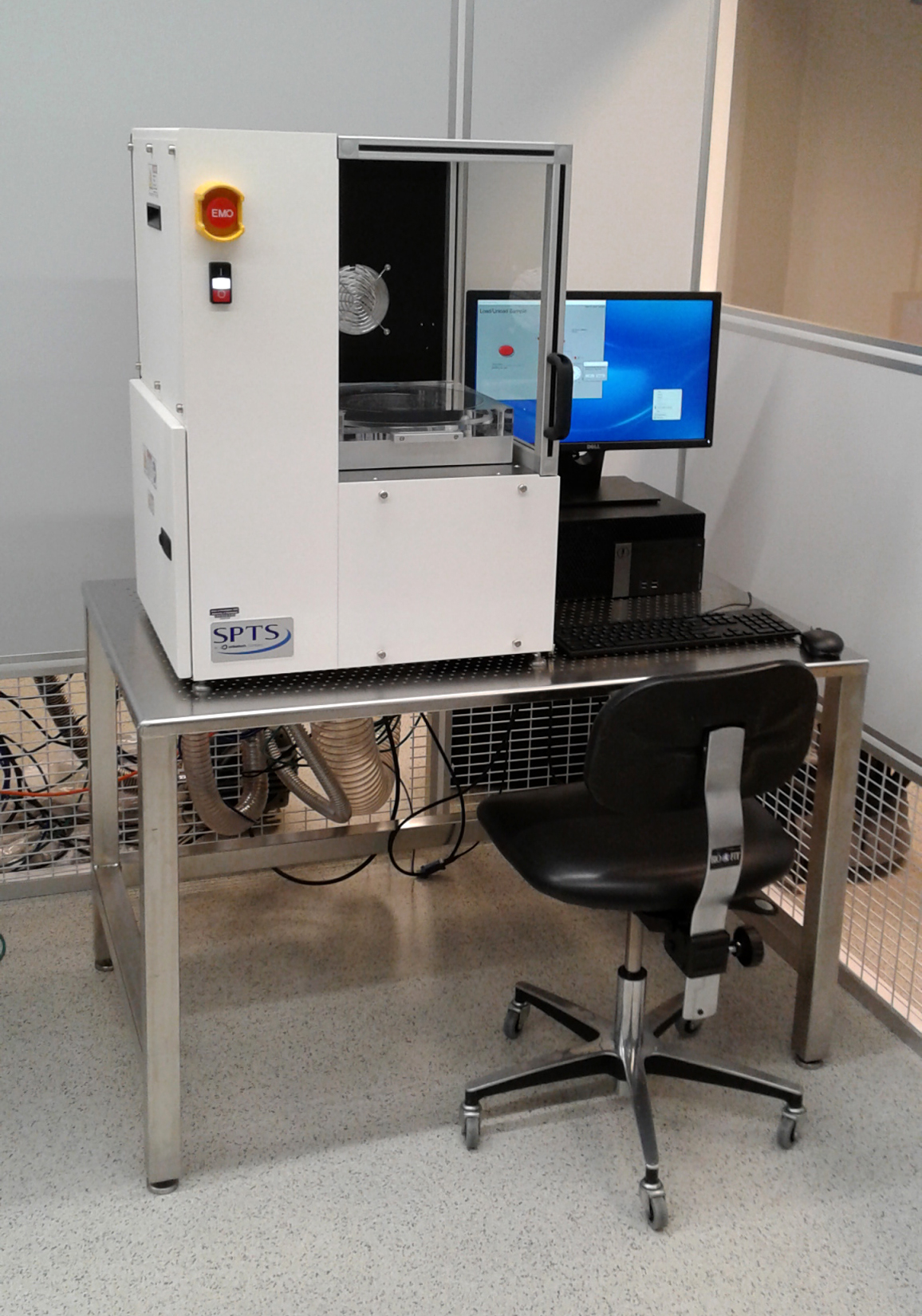

SPTS Silicon DRIE |

| |

|---|---|---|

| Coral ID: | WNF--DRIE2--SPTS | |

| Manufacturer: | SPTS | |

| Model: | Rapier Si_DRIE | |

| Lab: | WNF | |

| Area: | Dry Etch | |

| Manual: | SPTS-DRIE SOP v8_11_15_2024.pdf | |

| UW Academic Rate: | $77/hr | |

| Industrial Rate: | $231/hr | |

| Outside Academic Rate: | $77/hr | |

Description

The SPTS Rapier is a highly functional inductively coupled ion etch tool that uses a time-multiplexed SF6-C4F8 process, also known as the Bosch Process. The parameter space for this tool is extensive and getting lost therein easily done. Several pseudo-standard recipes are available as starting points, but most processing on this tool will require some development. We're here to help.

Details

(none given)

Materials Restrictions

Etch target material is limited to silicon with mask material restricted to silicon oxide, silicon nitride, photoresist and e-beam resist. Wafer size is limited to 100mm only. It is not permitted to etch through wafer without a carrier or handle wafer between the etch target and the chuck. Note: No exposed metals (including copper, gold, and silver). Contact tool owner regarding restriction details.

SPTS uEtch Module HF Vapor etcher |

| |

|---|---|---|

| Coral ID: | WNF--Vapor-Etch--HF | |

| Manufacturer: | SPTS | |

| Model: | MicroEtch | |

| Lab: | WNF | |

| Area: | Dry Etch | |

| Manual: | HFVapor-Etch_v2.pdf | |

| UW Academic Rate: | $77/hr | |

| Industrial Rate: | $231/hr | |

| Outside Academic Rate: | $77/hr | |

Description

This HF Vapor Dry Etch system is configured with Hydrofluoric and Ethanol vapor used, primarily, for isotropic etching of silicon dioxide without a plasma. The HFVapor system etches at reduced pressure and 45C to isotropically etch sacrificial silicon oxide layers, primarily to release silicon microstructures in MEMS devices. The dry process avoids stiction of released moving parts and damage to delicate structures – common issues with conventional wet processing technology. This is a single wafer system for 4 inch to 8 inch wafers and dies on a carrier wafer.

Details

Etch target is primarily silicon dioxide. Recommended mask materials are silicon, Al, Au, Cr, Ni, SiC, Al2O3, LPCVD nitride. PECVD nitride is NOT recommended as a masking material.

Materials Restrictions

POLYMERS INCLUDING PHOTO/EBEAM RESIST ARE NOT ALLOWED IN THIS SYSTEM. No polymers (including photo nor ebeam resists), no Kapton tape is allowed in the tool. Additional materials NOT ALLOWED: doped oxide, doped glass, borosilicate glass, soda-lime glass, float-glass, pyrex, Ti, TiO2, and copper. Do not use materials other than those known as approved. If a material that is not listed here, please contact the tool owner.

Xenon Difluoride vapor etcher |

| |

|---|---|---|

| Coral ID: | WNF--Vapor-Etch--XeF2 | |

| Manufacturer: | SPTS | |

| Model: | e2 | |

| Lab: | WNF | |

| Area: | Dry Etch | |

| Manual: | XeF2Vapor-Etch_v1.2c.pdf | |

| UW Academic Rate: | $77/hr | |

| Industrial Rate: | $231/hr | |

| Outside Academic Rate: | $77/hr | |

Description

The XeF2 vapor etch tool is for primarily for isotropic chemical etching of silicon sacrificial layers for the release of MEMS structures.

Details

Xenon difluoride (XeF2) provides a highly selective isotropic etch for Si, Mo and Ge and is an ideal solution for etching sacrificial layers to “release” moving components within MEMS devices. It provides numerous unique advantages and capabilities compared to wet and SF6 plasma etch options. The process is generally carried out at pressures between 0.5 and 4 torr providing controlled, stiction-free and residue-free etching. Typical vertical and lateral silicon etch rates are in the 0.1 - 10 microns/minute range. Because of its selectivity and excellent reach, XeF2 can be used to make very long undercuts with little or no degradation of etch stop, mask or device layers. Silicon dioxide masks, with a Si:oxide selectivity of >1,000:1, have been used to achieve very long undercuts (well over 100μm) and to protect extremely small or thin devices (less than 30nm). XeF2 does not attack polymers or other organic films. Photoresist can be used as a cost-effective mask and polymeric passivation layers, such as those from the Bosch Process, can be used as an effective protective layer for trench sidewalls. XeF2 is also an ideal way to release PDMS, parylene, and SU8. Since XeF2 does not etch packing and dicing materials, it can increase yield by delaying the release of a MEMS device until after dicing or package insertion and wire bonding. XeF2 has been used successfully to release MEMS devices on diced wafers and chips inside packages.

Materials Restrictions

Allowed etch target materials: silicon, germanium, molybdenum, SiGe, Ti, W. Allowed masks(typical selectivity): photo/ebeam resists, PDMS, silicon dioxide(1000:1), silicon nitride(100:1), Au, Al, Ni, Cr, Pt, SiC. DO NOT use this tool for thinning silicon wafers or to thin silicon chips. See tool owner for further information.

Inspection

Goniometer |

| |

|---|---|---|

| Coral ID: | WNF--Goniometer--OCA-20 | |

| Manufacturer: | OCA | |

| Model: | 20 | |

| Lab: | WNF | |

| Area: | Inspection | |

| Manual: | OCA Goniometer User Instructions Quick Guide.pdf | |

| UW Academic Rate: | $11/hr | |

| Industrial Rate: | $33/hr | |

| Outside Academic Rate: | $11/hr | |

Description

Is is a goniometer used to characterize solid-liquid interactions by optically measuring contact angles. It can accommodate samples from chips up to 200,, wafers.

Details

This tool uses backlighting and optics to measure contact angles between liquids and solid surfaces. Currently this tool is set up for DI water only

Materials Restrictions

Samples must be clean, dry, and leave no residue on the stage

Leica DVM2500 digital microscope |

| |

|---|---|---|

| Coral ID: | WNF--Microscope--Leica-Backend | |

| Manufacturer: | Leica | |

| Model: | DVM2500 | |

| Lab: | WNF | |

| Area: | Inspection | |

| UW Academic Rate: | $11/hr | |

| Industrial Rate: | $33/hr | |

| Outside Academic Rate: | $11/hr | |

Description

This digital microscope is capable of variable angles, has a long working distance, and has magnification from 20x to 160x,

Details

(none given)

Materials Restrictions

(none)

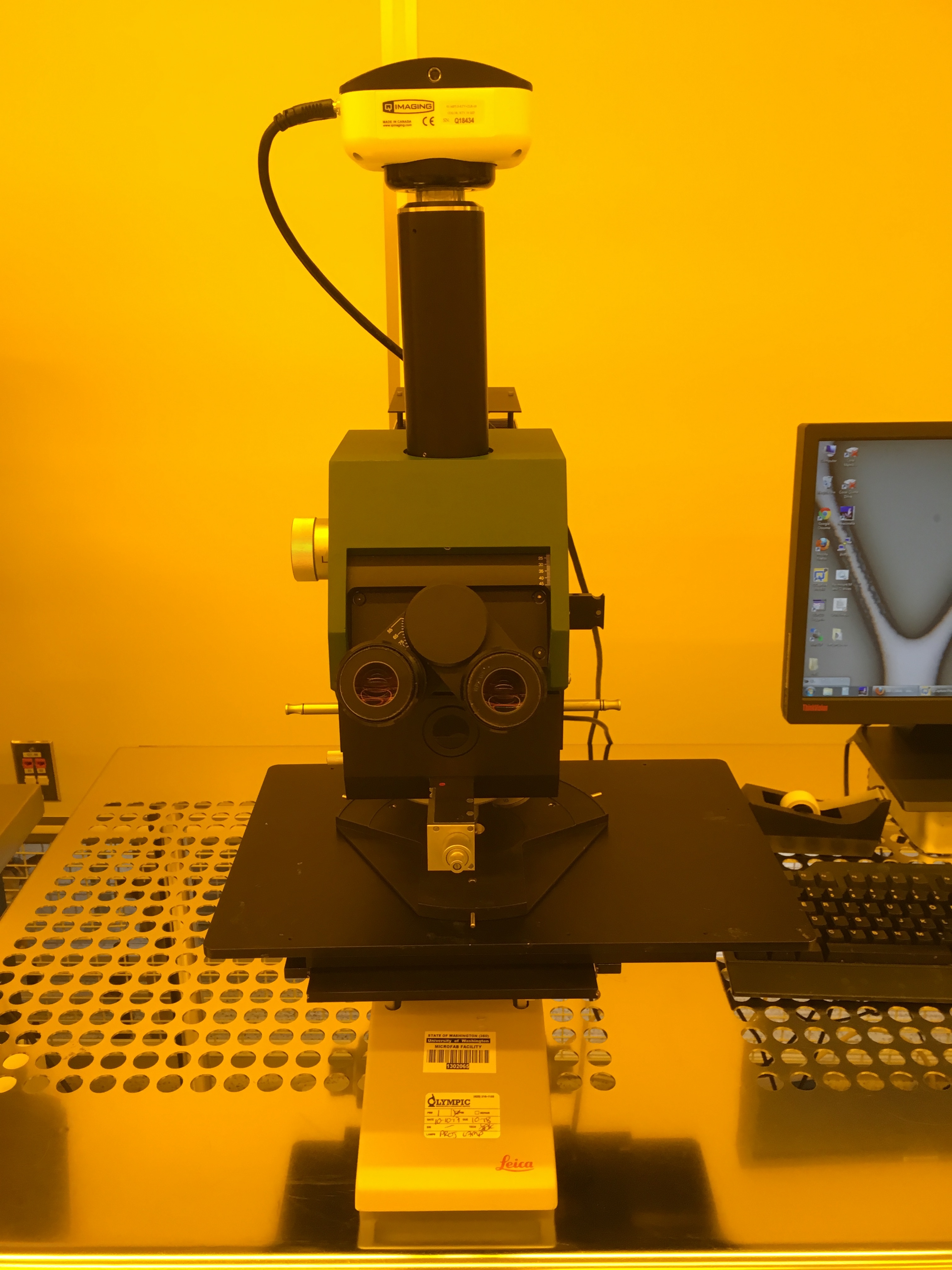

Leica Microscope |

| |

|---|---|---|

| Coral ID: | WNF--Microscope--Leica | |

| Manufacturer: | Leica / Reichert | |

| Model: | Polylite 88 | |

| Lab: | WNF | |

| Area: | Inspection | |

| UW Academic Rate: | $11/hr | |

| Industrial Rate: | $33/hr | |

| Outside Academic Rate: | $11/hr | |

Description

Priority inspection in support of wet chemistry and develop activities. NO WET MATERIALS ARE ALLOWED ON THE MICROSCOPE STAGE.

Microscope is not interlocked for ease of use. Users are expected to be logged into Wet Chem Bay A to use this asset.

Camera computer is interlocked in CORAL. Users undertaking dedicated inspection activities longer than 5-10 minutes should be logged into CORAL (not Bay A)

The microscope is capable of Nomarski imaging/DIC and has a stage that can accommodate wafers up to 150 mm.

Details

(none given)

Materials Restrictions

No Wet Materials allowed on Microscope Stage

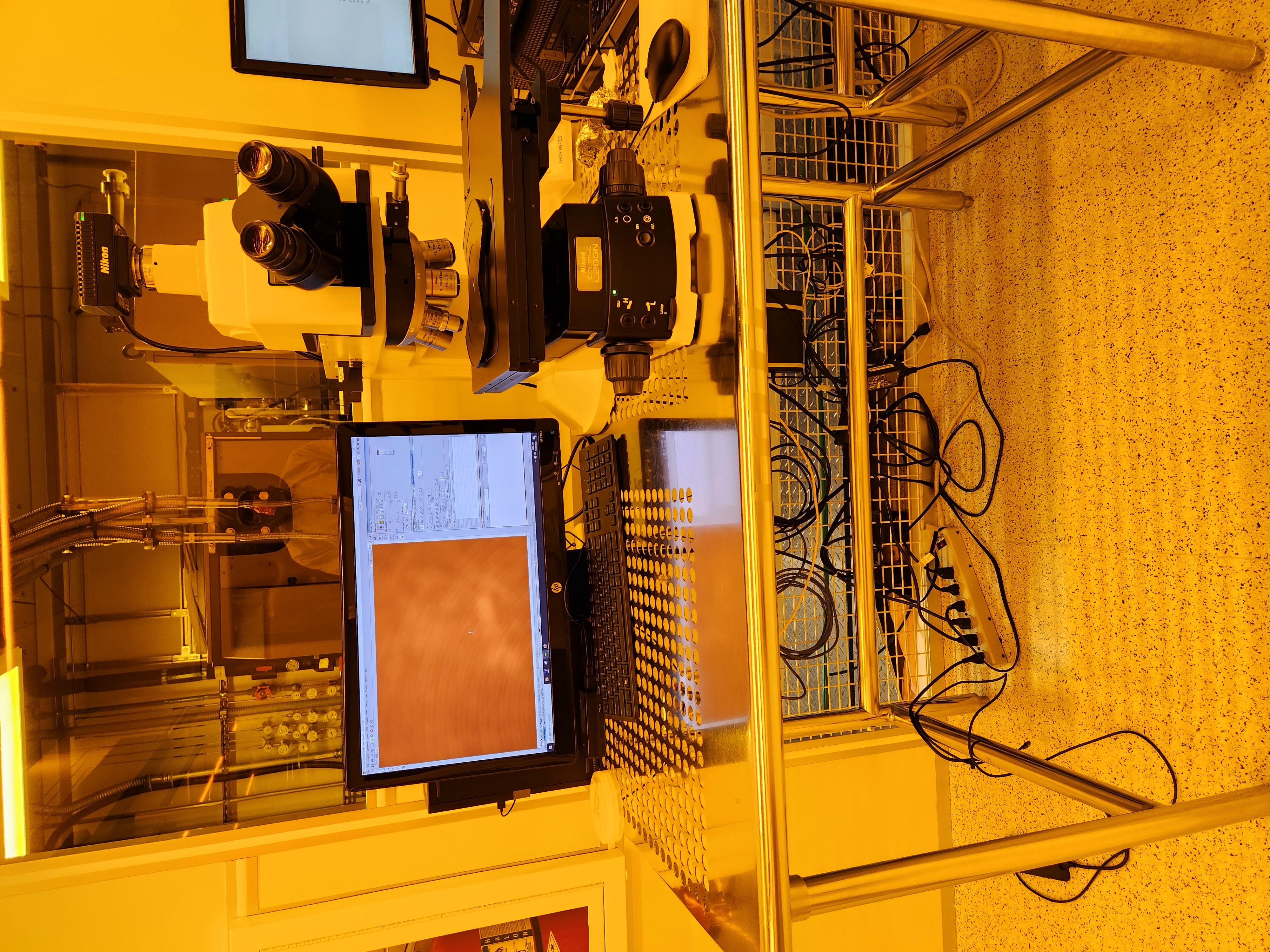

Nikon 6" Microscope | ||

|---|---|---|

| Coral ID: | WNF--Microscope08--Nikon | |

| Manufacturer: | Nikon | |

| Model: | LV150N | |

| Lab: | WNF | |

| Area: | Inspection | |

| UW Academic Rate: | $11/hr | |

| Industrial Rate: | $33/hr | |

| Outside Academic Rate: | $11/hr | |

Description

This is one of the primary imaging optical microscopes at the WNF. It includes five objectives (5X - 100X), an LED light source, a UV cutoff filter, and imaging in both bright field and dark field. It is capable of imaging clean samples as small as chips and as large as 150 mm wafers.

Details

(none given)

Materials Restrictions

(none)

Nikon 8" Imaging Microscope |

| |

|---|---|---|

| Coral ID: | WNF--Microscope09--Nikon | |

| Manufacturer: | Nikon | |

| Model: | Eclipse L200ND | |

| Lab: | WNF | |

| Area: | Inspection | |

| UW Academic Rate: | $11/hr | |

| Industrial Rate: | $33/hr | |

| Outside Academic Rate: | $11/hr | |

Description

This is the primary optical microscope for imaging of wafers at the WNF. It includes six objectives (2.5X - 100X), an LED light source, a UV cutoff filter, bright field and dark field imaging, and differential interference contrast. It is capable of imaging clean samples as small as chips and as large as 200 mm wafers.

Details

(none given)

Materials Restrictions

Clean and dry samples only. Resists must be properly baked. Nothing should be left behind on the stage after inspection.

Nikon Semiconductor Optical Microscope |

| |

|---|---|---|

| Coral ID: | WNF--Microscope--Nikon | |

| Manufacturer: | Optiphot | |

| Model: | 200 | |

| Lab: | WNF | |

| Area: | Inspection | |

| Manual: | 201309 Nikon Microscope.pdf | |

| UW Academic Rate: | $11/hr | |

| Industrial Rate: | $33/hr | |

| Outside Academic Rate: | $11/hr | |

Description

This optical microscope including dark-field imaging, LED light sources for both reflected and transmitted illumination, and a camera for image capture. The stage can accommodate wafers up to 200 mm in diameter as well as irregular samples.

Details

(none given)

Materials Restrictions

(none)

Wafer Inspection Tool |

| |

|---|---|---|

| Coral ID: | WNF--Wafer-Analyzer--Nanotronics-Nspec | |

| Manufacturer: | Nanotronics | |

| Model: | nSpec LS | |

| Lab: | WNF | |

| Area: | Inspection | |

| Manual: | Nanotronics SOP 20241027.pdf | |

| UW Academic Rate: | $55/hr | |

| Industrial Rate: | $165/hr | |

| Outside Academic Rate: | $55/hr | |

Description

Used for automated inspection of devices, repeating patterns, and full wafer defect mapping.

Details

Objectives: 2.5x, 5x, 10x, 20x, 50x

Illumination modes: bright field, dark field, differential interference contrast

Software rev 0.23.0.2 (as of 3-31-25)

Materials Restrictions

(none)

Lithography and Direct Patterning

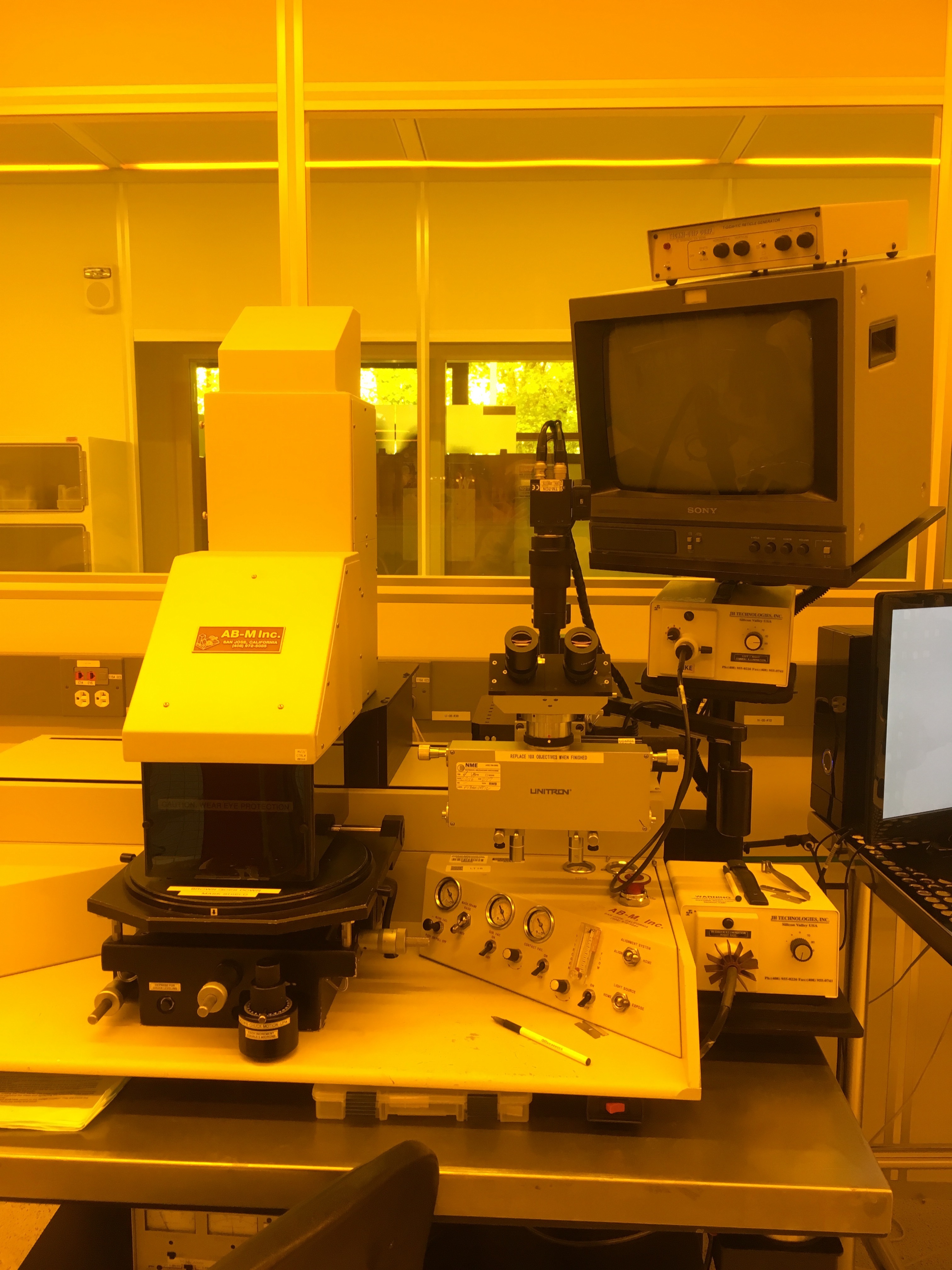

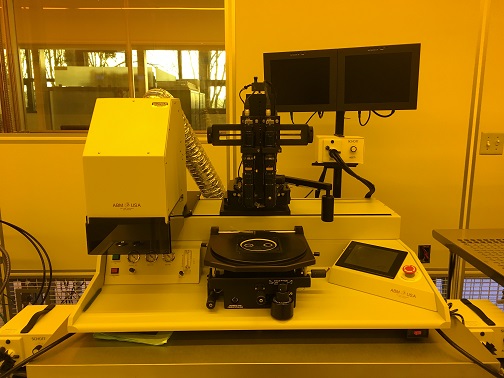

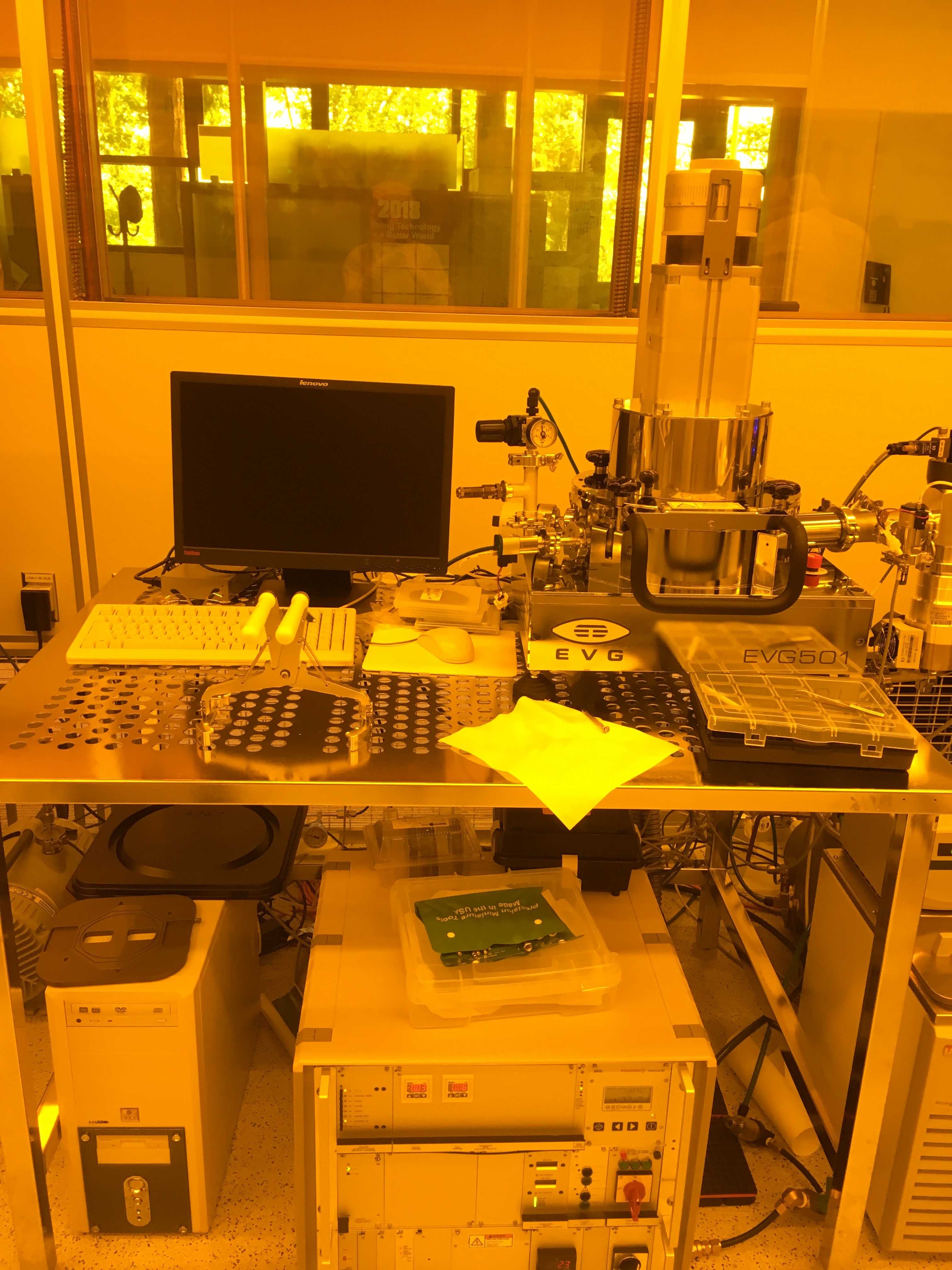

ABM Contact Aligner |

| |

|---|---|---|

| Coral ID: | WNF--Aligner--ABM | |

| Manufacturer: | AB-M | |

| Lab: | WNF | |

| Area: | Lithography and Direct Patterning | |

| Manual: | ABM SOP (Teaching Lab).pdf | |

| UW Academic Rate: | $55/hr | |

| Industrial Rate: | $165/hr | |

| Outside Academic Rate: | $55/hr | |

Description

Contact photolithography exposure tool for 100mm wafers. An optimized process can achieve 2 um line/space patterns with a layer-to-layer registration accuracy about 3 um.

Details

(none given)

Materials Restrictions

Uses 5in or 7in square photomasks with 0.090in thickness. Configured for exposure of 100mm wafers; smaller chips can be accomodated using a carrier wafer.

ACS200Gen3 Coat and Bake |

| |

|---|---|---|

| Coral ID: | WNF--Coater--Suss--ACS200 | |

| Manufacturer: | Suss MicroTec | |

| Model: | ACS200Gen3 Coat and Bake | |

| Lab: | WNF | |

| Area: | Lithography and Direct Patterning | |

| Manual: | ACS200_SOP_Feb2026.pdf | |

| UW Academic Rate: | $77/hr | |

| Industrial Rate: | $231/hr | |

| Outside Academic Rate: | $77/hr | |

Description

Automated coater cluster tool with 100mm and 150mm wafers. Auto dispenses AZ1512, AZ10XT, AZ701 and NR-9 3000 photoresists. Recipes often utilize frontside and backside EBR. Modules include: HMDS vapor prime, coater, cold plate and two vacuum bake ovens.

Details

(none given)

Materials Restrictions

(none)

ACS200Gen3 Coat, Develop and Bake System |

| |

|---|---|---|

| Coral ID: | WNF--Developer--Suss--ACS200 | |

| Manufacturer: | Suss MicroTec | |

| Model: | ACS200Gen3 Coat, Develop and Bake System | |

| Lab: | WNF | |

| Area: | Lithography and Direct Patterning | |

| Manual: | ACS200_SOP_Feb2026.pdf | |

| UW Academic Rate: | $77/hr | |

| Industrial Rate: | $231/hr | |

| Outside Academic Rate: | $77/hr | |

Description

Automated developer cluster tool with 100mm and 150mm capability. Auto dispenses AZ726 MIF and diluted AZ400K developers. Recipes utilize frontside and backside DI water rinse. Modules include: vacuum bake, cold plate, developer.

Details

(none given)

Materials Restrictions

(none)

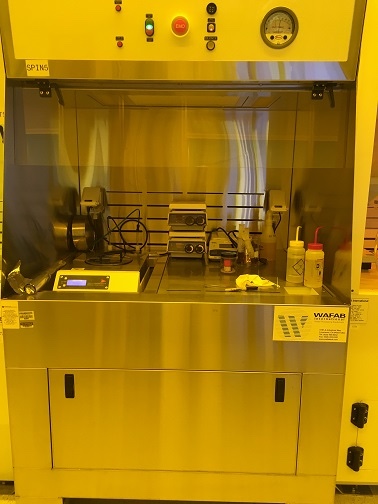

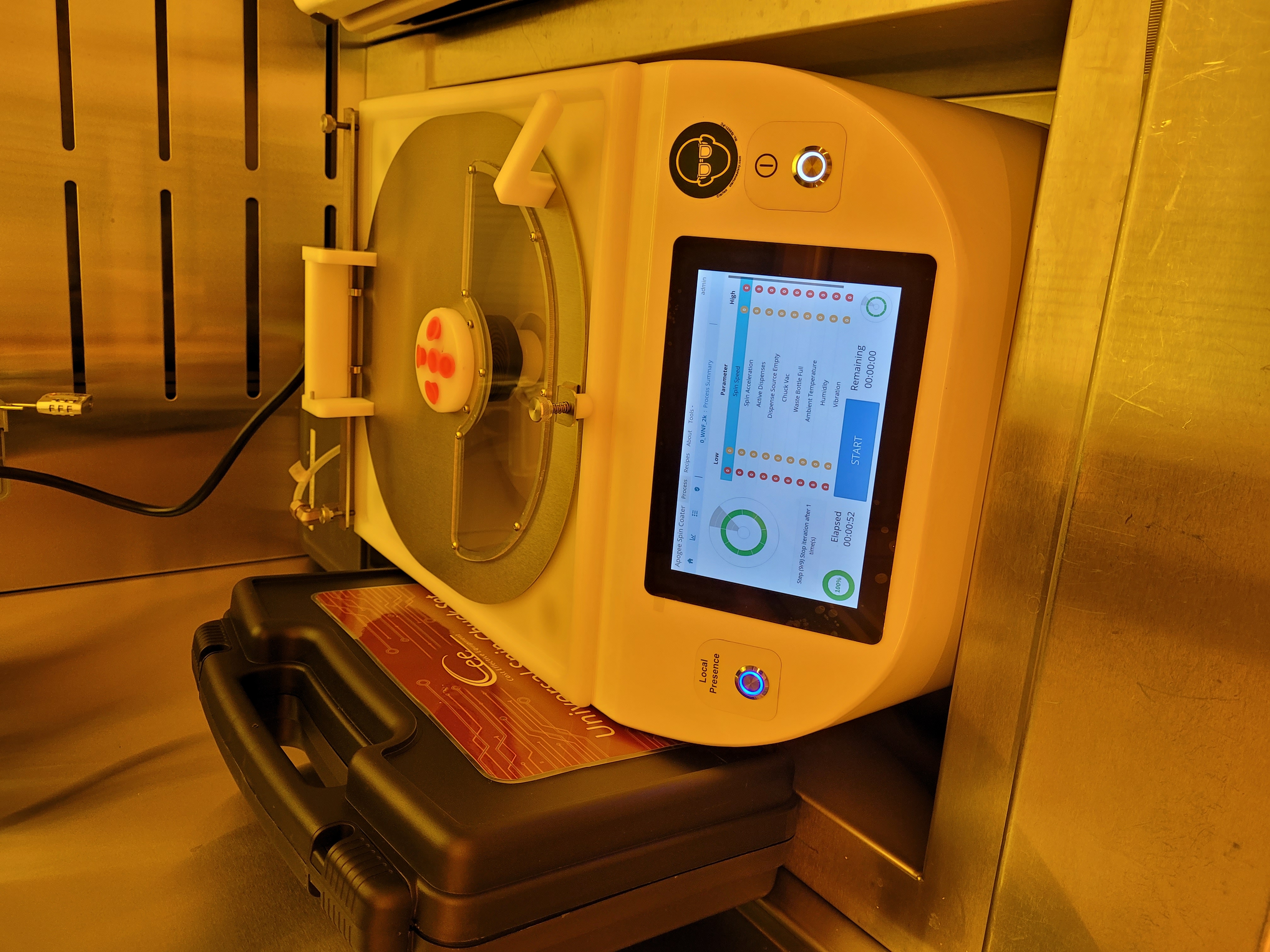

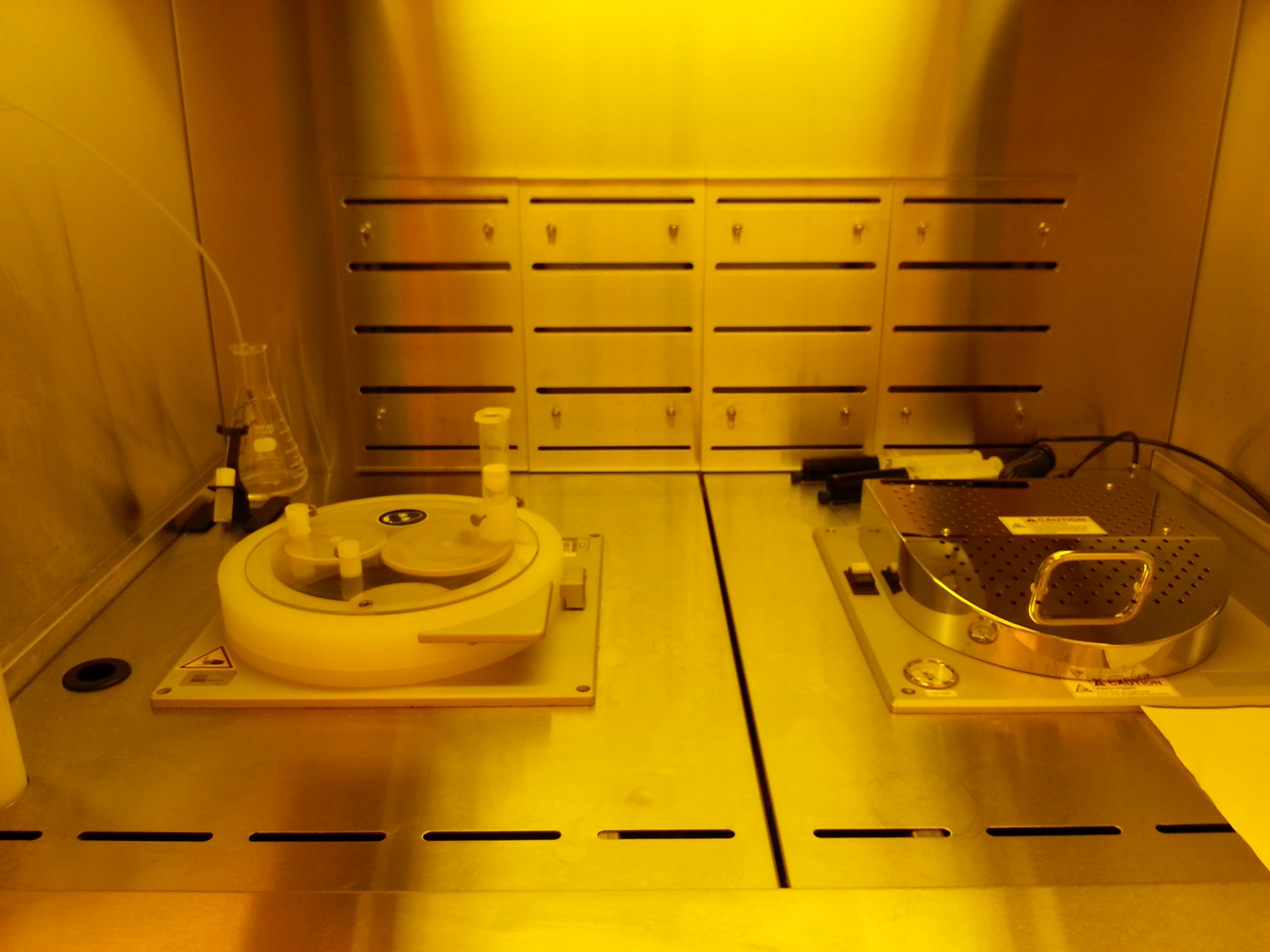

CEE Apogee Spin Coater |

| |

|---|---|---|

| Coral ID: | WNF--SPIN5 | |

| Manufacturer: | WAFAB | |

| Model: | 48" SST Front Acess Wet Bench | |

| Lab: | WNF | |

| Area: | Lithography and Direct Patterning | |

| Manual: | SPIN4_5_Apogee_SOP_V1.2.pdf | |

| UW Academic Rate: | $55/hr | |

| Industrial Rate: | $165/hr | |

| Outside Academic Rate: | $55/hr | |

Description

Flexible, manual bench-top spin coater with vacuum chucks available for pieces from a few mm up to 150 mm wafers.

Details

(none given)

Materials Restrictions

(none)

DWL66+ Direct Write |

| |

|---|---|---|

| Coral ID: | WNF--MaskWriter--Heidelberg-DWL66plus | |

| Manufacturer: | Heidelberg | |

| Model: | DWL66+ | |

| Lab: | WNF | |

| Area: | Lithography and Direct Patterning | |

| Manual: | DWL66+ Basic SOP_Jan2025.pdf | |

| UW Academic Rate: | $33/hr | |

| Industrial Rate: | $99/hr | |

| Outside Academic Rate: | $33/hr | |

Description

Create masks or direct write on substrates with alignment capability utilizing a 405nm laser. Write modes HiRes with 300nm minimum feature, 4mm head with 0.8um minimum feature, and 20mm head with 2um minimum feature.

Details

(none given)

Materials Restrictions

(none)

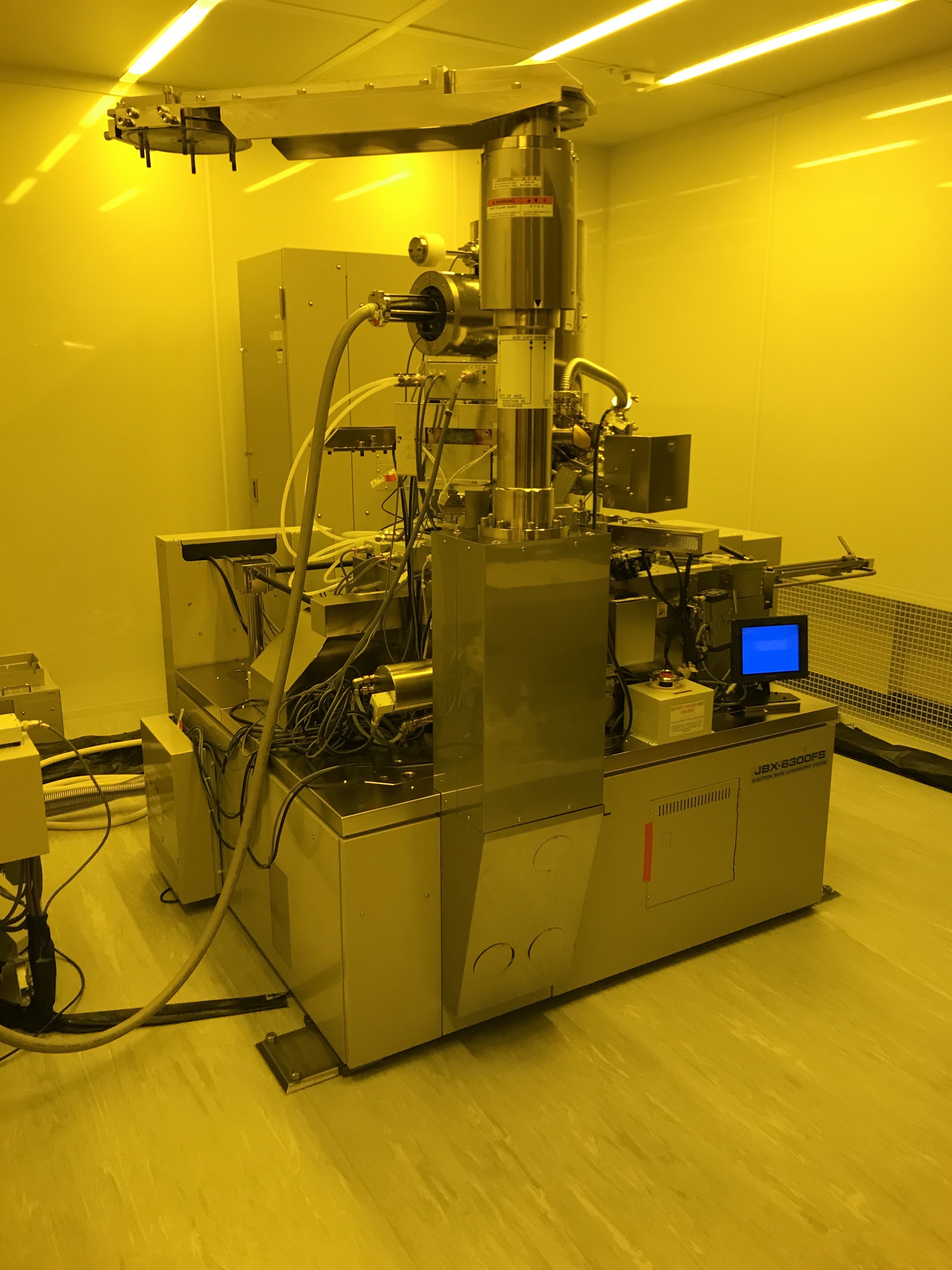

EBL01--JEOL-6300FS |

| |

|---|---|---|

| Coral ID: | WNF--EBL--JEOL-JBX6300FS | |

| Manufacturer: | JEOL | |

| Model: | JBX6300FS | |

| Lab: | WNF | |

| Area: | Lithography and Direct Patterning | |

| UW Academic Rate: | $137/hr | |

| Industrial Rate: | $495/hr | |

| Outside Academic Rate: | $137/hr | |

Description

Direct-write 100 kV Electron Beam Lithography capable of feature sizes as small as 10 nm, and layer-to-layer registration better than ~30 nm m+3s.

Details

Substrates from small chips to 150mm wafers. A wide range of beam currents, choice of two objective lenses, and a wide range of resist processes provide significant flexibility for a variety of needs. Sophisticated data preparation software provides advanced functions including full shape and dose proximity correction.

Materials Restrictions

All materials must be explicitly approved by staff.

HMDS/Image Reversal Oven |

| |

|---|---|---|

| Coral ID: | WNF--YES-Oven | |

| Manufacturer: | Yield Engineering Systems | |

| Model: | YES-58 | |

| Lab: | WNF | |

| Area: | Lithography and Direct Patterning | |

| Manual: | YES58-Oven_SOP_20241125.pdf | |

| UW Academic Rate: | $33/hr | |

| Industrial Rate: | $99/hr | |

| Outside Academic Rate: | $33/hr | |

Description

HMDS oven for priming wafers. Has image reversal capability, but ammonia is currently not hooked up to the system.

Details

(none given)

Materials Restrictions

(none)

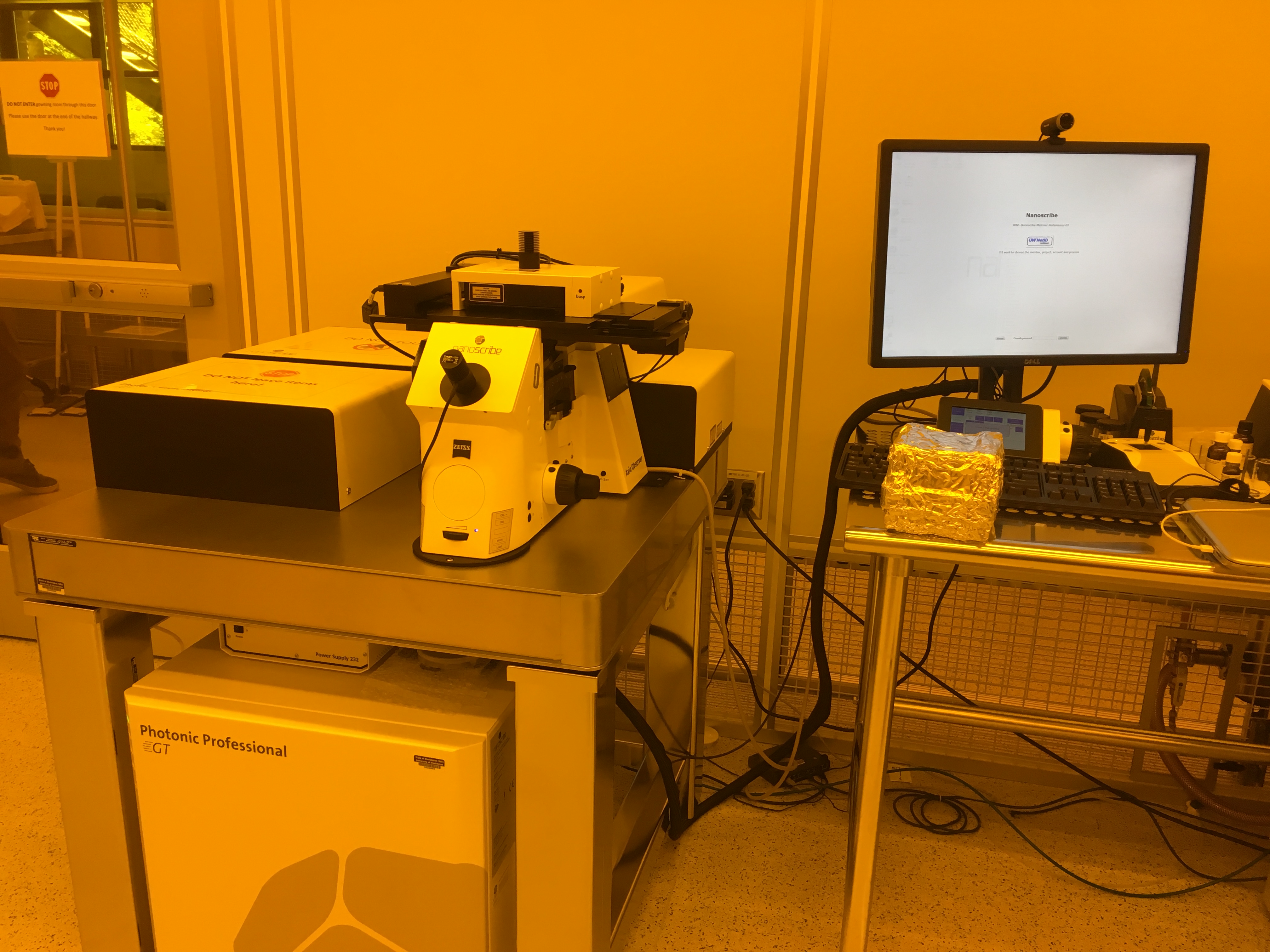

Nanoscribe Photonic Professional GT |

| |

|---|---|---|

| Coral ID: | WNF--Nanoscribe-Photonic-Professional-GT | |

| Manufacturer: | Nanoscribe | |

| Model: | Photonic Professional (GT) | |

| Lab: | WNF | |

| Area: | Lithography and Direct Patterning | |

| Manual: | Nanoscribe SOP 2.0.pdf | |

| UW Academic Rate: | $33/hr | |

| Industrial Rate: | $99/hr | |

| Outside Academic Rate: | $33/hr | |

Description

3D printing platform for micro- and nanofabrication demands utilizing two-photon polymerization. Structures can either be designed in 3D printer compatible CAD software programs or directly implemented in Nanoscribe’s GWL scripting language.

Details

(none given)

Materials Restrictions

(none)

Semi-Auto AB-M |

| |

|---|---|---|

| Coral ID: | WNF--ABM-SemiAuto-Aligner | |

| Manufacturer: | ABM | |

| Model: | Semi-Auto | |

| Lab: | WNF | |

| Area: | Lithography and Direct Patterning | |

| Manual: | ABM-SemiAuto_SOP_Sept2024.pdf | |

| UW Academic Rate: | $55/hr | |

| Industrial Rate: | $165/hr | |

| Outside Academic Rate: | $55/hr | |

Description

Semi-auto contact photolithography exposure tool for 100mm wafers. Capable of front to back alignment utilizing IR.

Details

(none given)

Materials Restrictions

(none)

Solvent Bench |

| |

|---|---|---|

| Coral ID: | WNF--BATH6-Strip | |

| Manufacturer: | WAFAB | |

| Model: | 72" SST Front Acess | |

| Lab: | WNF | |

| Area: | Lithography and Direct Patterning | |

| Manual: | BATH6-Strip_2.0.pdf | |

Description

Solvent bench with an EKC photoresist stripping bath and a sonicator for liftoff processing.

Details

Refilled weekly

Materials Restrictions

(none)

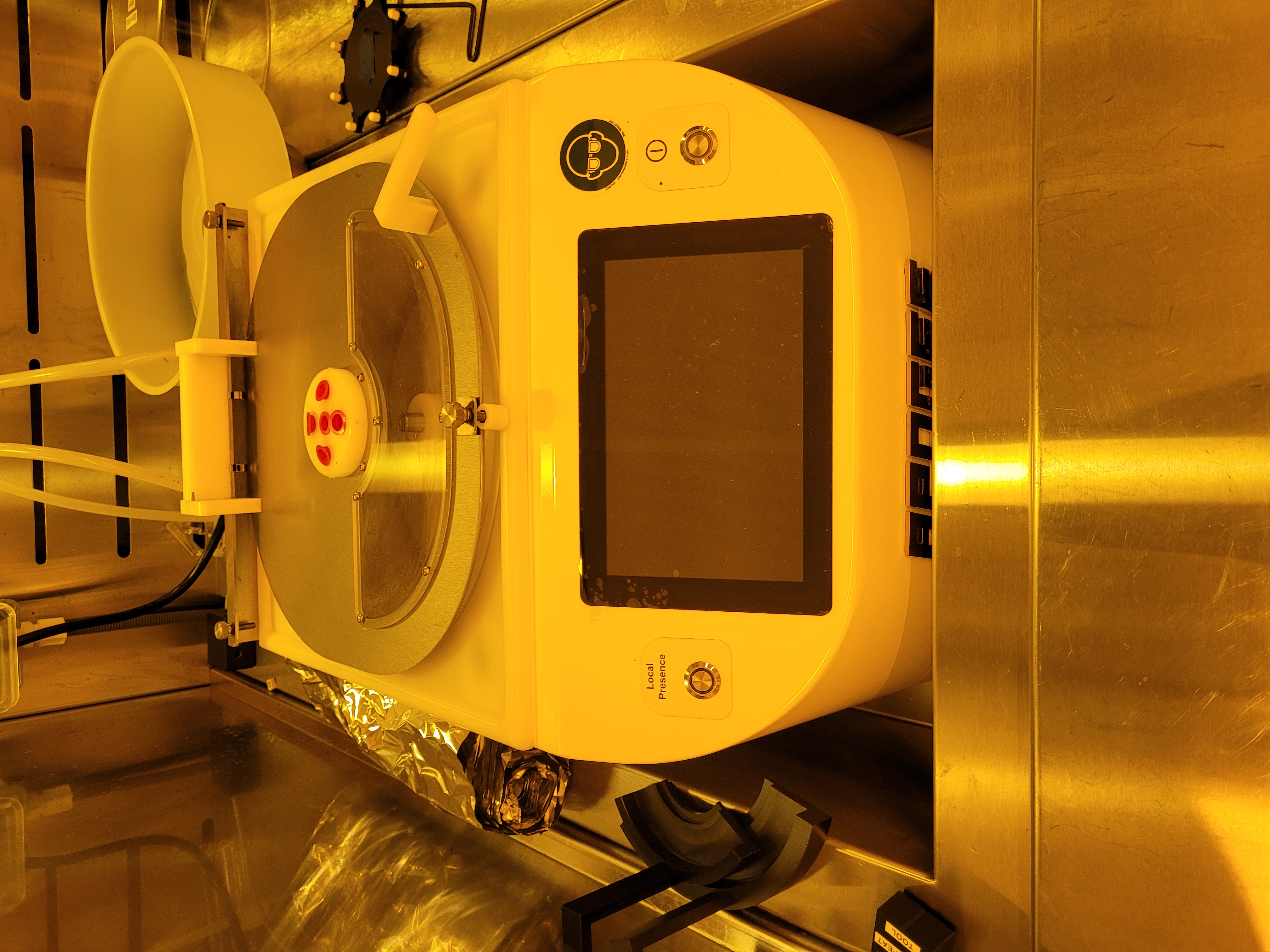

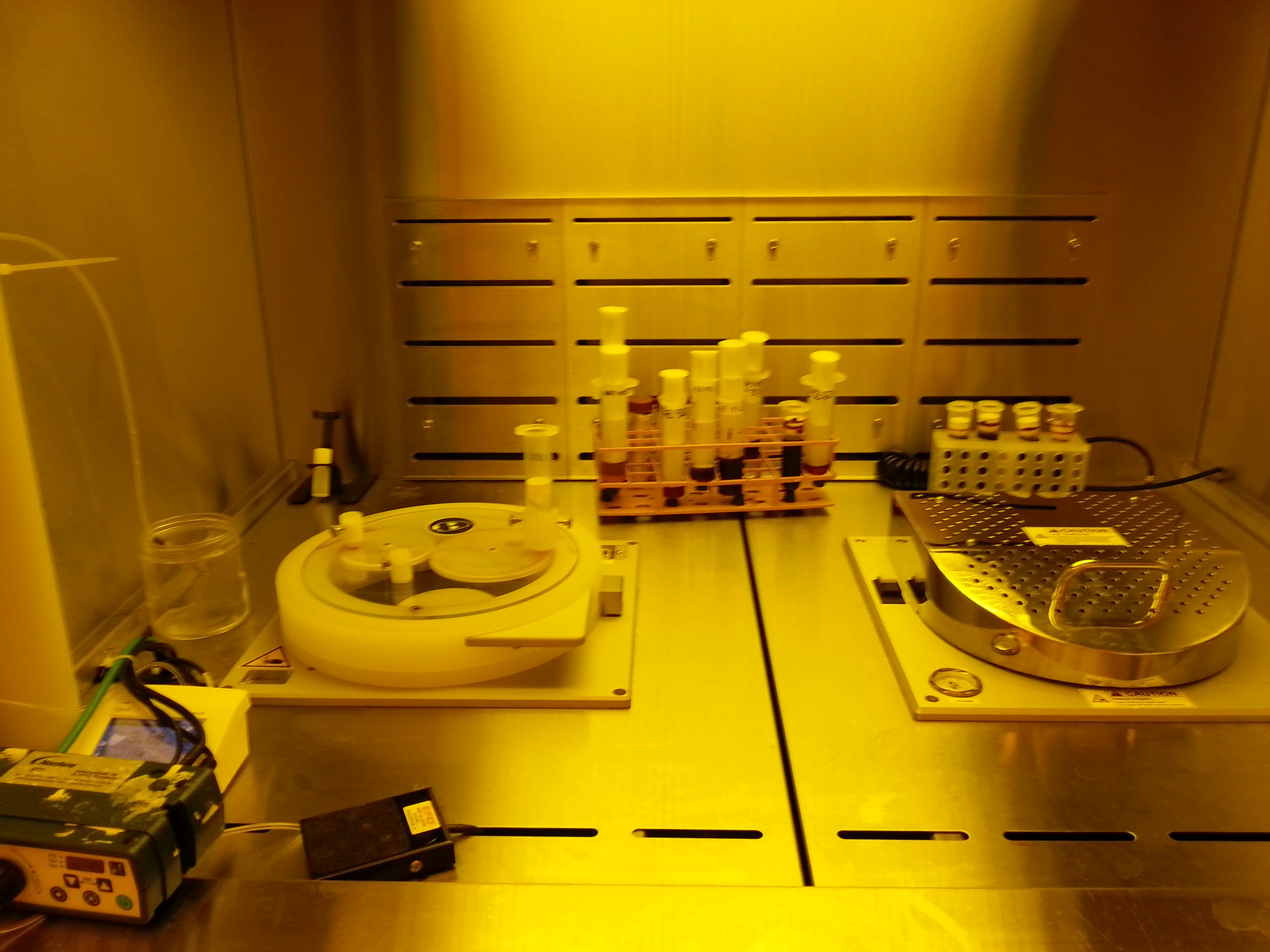

Spin Coater |

| |

|---|---|---|

| Coral ID: | WNF--SPIN3-EBeam | |

| Manufacturer: | Cost Effective Equipment | |

| Model: | APOGEE SPIN | |

| Lab: | WNF | |

| Area: | Lithography and Direct Patterning | |

| Manual: | SPIN3_Apogee_SOP_V1.3.pdf | |

| UW Academic Rate: | $55/hr | |

| Industrial Rate: | $165/hr | |

| Outside Academic Rate: | $55/hr | |

Description

Manual, benchtop spin coater with vacuum chucking for samples from a few mm to 200mm wafers.

Details

(none given)

Materials Restrictions

Limited to use for Electron Beam Resists only!

Spin Coater |

| |

|---|---|---|

| Coral ID: | WNF--SPIN4-General | |

| Manufacturer: | CEE | |

| Model: | APOGEE SPIN | |

| Lab: | WNF | |

| Area: | Lithography and Direct Patterning | |

| Manual: | SPIN4_5_Apogee_SOP_V1.2.pdf | |

| UW Academic Rate: | $55/hr | |

| Industrial Rate: | $165/hr | |

| Outside Academic Rate: | $55/hr | |

Description

Flexible, manual bench-top spin coater with vacuum chucks available for pieces from a few mm up to 200 mm wafers.

Details

(none given)

Materials Restrictions

(none)

Suss MicroTec MABA8 Aligner |

| |

|---|---|---|

| Coral ID: | WNF--Aligner--Suss | |

| Manufacturer: | Suss MicroTec | |

| Model: | MABA8 Gen4Pro | |

| Lab: | WNF | |

| Area: | Lithography and Direct Patterning | |

| Manual: | MABA8_SOP_Feb2026.pdf | |

| UW Academic Rate: | $55/hr | |

| Industrial Rate: | $165/hr | |

| Outside Academic Rate: | $55/hr | |

Description

A semi-automated mask and bond aligner. System can perform contact and proximity alignment and exposure on substrates ranging from 10mmx10mm to 150mm (6") diameter. System is also used to aligning substrates for wafer bonding on the Suss SB8GEN2 Universal Bonder.

Details

(none given)

Materials Restrictions

Masks must be 5" or 7". Substrates from 10mmx10mm to 150mm (6") diameter can be accommodated with some restrictions on smaller substrates.

Suss Spin Coater |

| |

|---|---|---|

| Coral ID: | WNF--SPIN2 | |

| Manufacturer: | Suss Microtec | |

| Model: | LabSpin8 | |

| Lab: | WNF | |

| Area: | Lithography and Direct Patterning | |

| Manual: | SPIN1_2_SOP_2022.pdf | |

| UW Academic Rate: | $55/hr | |

| Industrial Rate: | $165/hr | |

| Outside Academic Rate: | $55/hr | |

Description

Spin 100-200mm wafers, with a programmable controller, in a class 10 mini-environment, and a dedicated, electro-polished hotplate with automated wafer lift pins.

Details

(none given)

Materials Restrictions

(none)

Suss Spin Coater |

| |

|---|---|---|

| Coral ID: | WNF--SPIN1 | |

| Manufacturer: | Suss Microtec | |

| Model: | LabSpin8 | |

| Lab: | WNF | |

| Area: | Lithography and Direct Patterning | |

| Manual: | SPIN1_2_SOP_2022.pdf | |

| UW Academic Rate: | $55/hr | |

| Industrial Rate: | $165/hr | |

| Outside Academic Rate: | $55/hr | |

Description

Spin 100-200mm wafers, with a programmable controller, in a class 10 mini-environment, and a dedicated, electro-polished hotplate with automated wafer lift pins.

Details

(none given)

Materials Restrictions

(none)

Thinky Mixer |

| |

|---|---|---|

| Coral ID: | WNF--Thinky-Mixer | |

| Manufacturer: | Thinky | |

| Lab: | WNF | |

| Area: | Lithography and Direct Patterning | |

| UW Academic Rate: | $11/hr | |

| Industrial Rate: | $33/hr | |

| Outside Academic Rate: | $11/hr | |

Description

The Thinky mixer is used to mix and degas PDMS.

Details

(none given)

Materials Restrictions

(none)

Vacuum Oven |

| |

|---|---|---|

| Coral ID: | WNF--VacOven--Accutemp | |

| Manufacturer: | Across International | |

| Model: | ACCUTEMP-09 | |

| Lab: | WNF | |

| Area: | Lithography and Direct Patterning | |

| Manual: | Vacuum Drying Oven 20210505.pdf | |

| UW Academic Rate: | $11/hr | |

| Industrial Rate: | $33/hr | |

| Outside Academic Rate: | $11/hr | |

Description

Programmable vacuum oven with N2 backfill capability.

Details

Vacuum levels ranging from 1atm to ~0.5torr and equipped with an N2 backfill capability for inert environment. Operating temperature up to 250C, accuracy within +/- 1C. Can be programmed to automatically control a multi-segment drying process.

Materials Restrictions

(none)

YES Downstream Asher |

| |

|---|---|---|

| Coral ID: | WNF--Etcher--Yes-Asher | |

| Manufacturer: | Yield Engineering Systems (YES) | |

| Model: | YES CV200 RFS | |

| Lab: | WNF | |

| Area: | Lithography and Direct Patterning | |

| Manual: | ASH2-YES_UserManual_v5.pdf | |

| UW Academic Rate: | $77/hr | |

| Industrial Rate: | $231/hr | |

| Outside Academic Rate: | $77/hr | |

Description

Downstream asher used to remove organics from various materials. Available process gases: O2, Argon, N2

Details

A heated, tray-load system, the YES Downstream Asher offers a high degree of process control with 3 available process gases. The tool has 4 standard recipes for thin film resist stripping, thick film resist stripping, and substrate descum. Users are requested to work with the tool owner to develop process specific recipes.

Materials Restrictions

Allowed etch target materials: Photoresist, e-beam resist, organic contaminants, some polymers (No SU8 nor PDMS.) No high-vapor-pressure materials. Please contact tool owner to discuss materials not included on this list.

YES HMDS Oven |

| |

|---|---|---|

| Coral ID: | WNF--HMDS | |

| Manufacturer: | Yeild Enginerring Systems | |

| Model: | LP 3 A | |

| Lab: | WNF | |

| Area: | Lithography and Direct Patterning | |

| Manual: | HMDS_SOP_2024c.pdf | |

| UW Academic Rate: | $33/hr | |

| Industrial Rate: | $99/hr | |

| Outside Academic Rate: | $33/hr | |

Description

HMDS oven used for priming wafers prior to resist coating

Details

(none given)

Materials Restrictions

(none)

Other

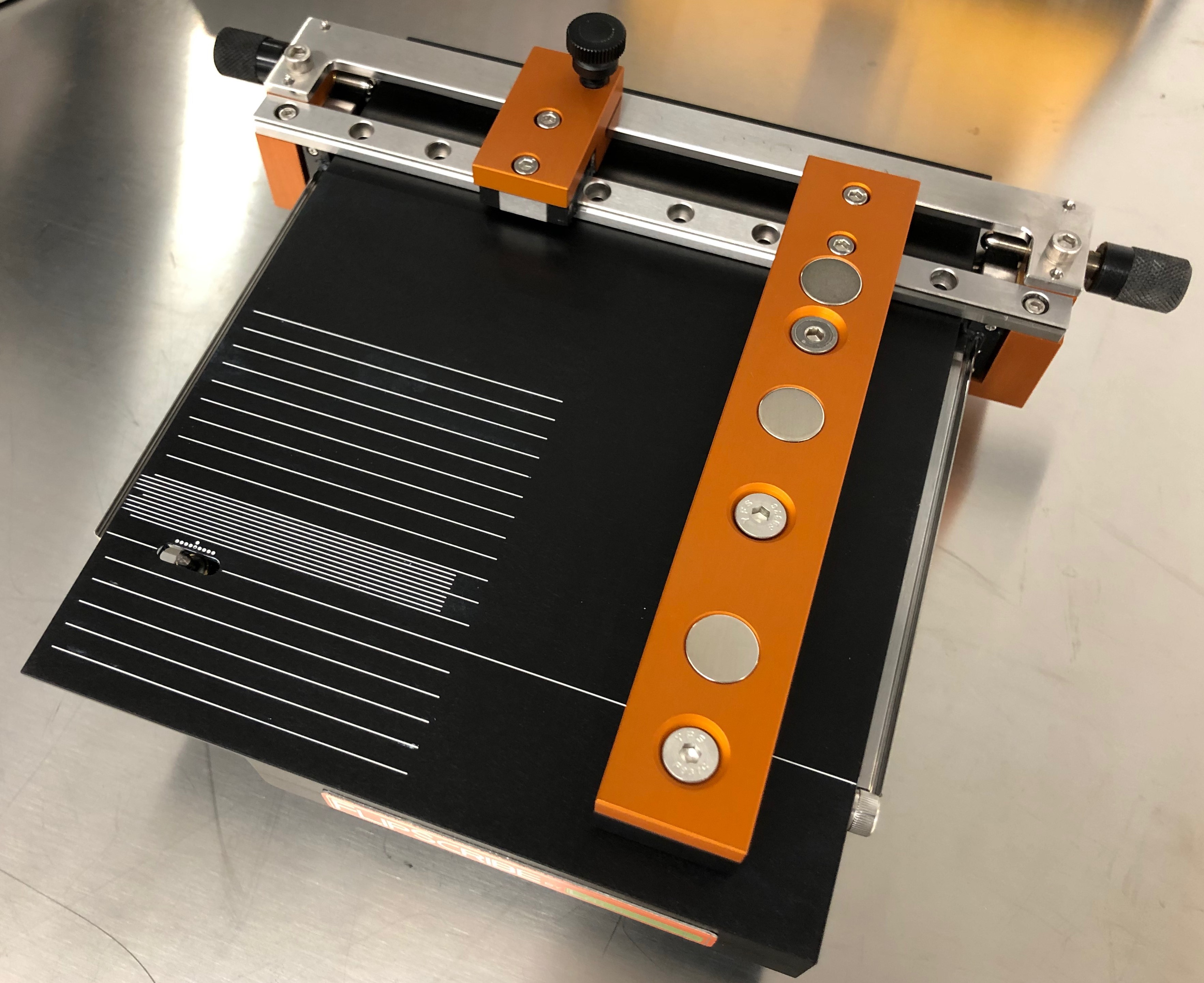

Wafer Scriber |

| |

|---|---|---|

| Coral ID: | WNF--Scriber--LatticeGear-FlipScribe | |

| Manufacturer: | LatticeGear | |

| Model: | FlipScribe | |

| Lab: | WNF | |

| Area: | Other | |

| UW Academic Rate: | $0/hr | |

| Industrial Rate: | $0/hr | |

| Outside Academic Rate: | $0/hr | |

Description

Manual scribing fixture for full and partial wafers, specifically designed for scribing the back side of the sample. Scribes across full wafers are possible, which is especially helpful for glass.

Details

4" wafer and small sample holders are available. Others are possible to obtain, please discuss specific needs with staff.

Materials Restrictions

Glass, sapphire, semiconductors. Dry samples only.

Packaging and Back End

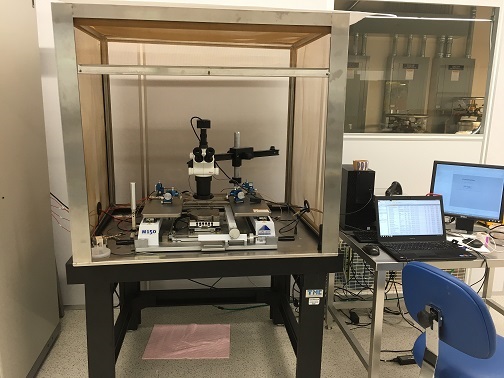

Cascade Microtech M150 |

| |

|---|---|---|

| Coral ID: | WNF--ProbeStation | |

| Manufacturer: | Cascade Microtech | |

| Model: | M150 | |

| Lab: | WNF | |

| Area: | Packaging and Back End | |

| UW Academic Rate: | $33/hr | |

| Industrial Rate: | $99/hr | |

| Outside Academic Rate: | $33/hr | |

Description

This manual probe station is typically used to measure conductivity, IV curves, and capacitance. It can be configured for many measurements and has a camera capable of recording video of moving MEMS devices.

Details

(none given)

Materials Restrictions

(none)

Disco Wafer Backgrinder | ||

|---|---|---|

| Coral ID: | WNF--Grinder--Disco | |

| Manufacturer: | Disco America | |

| Model: | DAG810 | |

| Lab: | WNF | |

| Area: | Packaging and Back End | |

| Manual: | DAG810_SOP1.2.pdf | |

| UW Academic Rate: | $77/hr | |

| Industrial Rate: | $231/hr | |

| Outside Academic Rate: | $77/hr | |

Description

Wafer backgrinder capable of bulk grinding and thinning of 200mm diameter wafers and smaller, including chips.

Details

(none given)

Materials Restrictions

No metals; wastestream safe materials only

Disco Wafer Dicer |

| |

|---|---|---|

| Coral ID: | WNF--Saw--Disco | |

| Manufacturer: | Disco America | |

| Model: | DAD321 | |

| Lab: | WNF | |

| Area: | Packaging and Back End | |

| Manual: | DiscoDAD SOP 3.2.pdf | |

| UW Academic Rate: | $55/hr | |

| Industrial Rate: | $165/hr | |

| Outside Academic Rate: | $55/hr | |

Description

Wafer dicing capable of 150mm diameter wafers and smaller.

Details

(none given)

Materials Restrictions

Silicon, glass, sapphire, other semiconductors crystalline structures. No bulk metal dicing; stack materials must be wastestream safe.

EVG Bonder |

| |

|---|---|---|

| Coral ID: | WNF--Bonder--Suss | |

| Manufacturer: | Suss MicroTec | |

| Model: | SUSS SB8GEN2 Universal Bonder | |

| Lab: | WNF | |

| Area: | Packaging and Back End | |

| Manual: | EVGBond_SOPv1.4.pdf | |

| UW Academic Rate: | $77/hr | |

| Industrial Rate: | $231/hr | |

| Outside Academic Rate: | $77/hr | |

Description

Anodic, eutectic, and fusion bonding for Si and glass substrates.

Details

System can be set up by staff to run 100mm or 150mm wafers.

Materials Restrictions

(none)

Finetech Fineplacer pico |

| |

|---|---|---|

| Coral ID: | WNF--WireBonder--Flip-Chip | |

| Manufacturer: | Finetech | |

| Model: | Fineplacer pico | |

| Lab: | WNF | |

| Area: | Packaging and Back End | |

| Manual: | flipchip_SOP_2.1.pdf | |

| UW Academic Rate: | $55/hr | |

| Industrial Rate: | $165/hr | |

| Outside Academic Rate: | $55/hr | |

Description

This flip chip and die bonder can be used to place parts with better than 5um accuracy.

Details

(none given)

Materials Restrictions

(none)

Wafer Cleaver | .jpg)

| |

|---|---|---|

| Coral ID: | WNF--Cleaver--LatticeGear-AX420 | |

| Manufacturer: | LatticeGear | |

| Model: | AX420 | |

| Lab: | WNF | |

| Area: | Packaging and Back End | |

| Manual: | Cleaver - LatticeGear AX420 SOP 20180328.pdf | |

| UW Academic Rate: | $33/hr | |

| Industrial Rate: | $99/hr | |

| Outside Academic Rate: | $33/hr | |

Description

Precision diamond indentation and break station

Details

(none given)

Materials Restrictions

Recommended for single crystal semiconductor wafers

WEST-BOND Wire Bonder |

| |

|---|---|---|

| Coral ID: | WNF--WestBond | |

| Manufacturer: | WestBond | |

| Model: | 4700E | |

| Lab: | WNF | |

| Area: | Packaging and Back End | |

| Manual: | Westbond wirebonder SOP 2.2 - CURRENT.pdf | |

| UW Academic Rate: | $55/hr | |

| Industrial Rate: | $165/hr | |

| Outside Academic Rate: | $55/hr | |

Description

Wire bonding is used to electrically connect semiconductor devices with their packaging. The Westbond 4700E is a semiautomatic thermosonic ball-wedge wire bonder. It can be used to quickly lay down a succession of shaped electrical interconnects, or simple stud bumps for bonding chips using the flip chipper. The shaping and bonding of the wire is automated while the X-Y placement is manual, making it ideal for quickly generating testable prototypes and small batches of working devices.

The wire is 1 mil (25um) gold wire.

Details

(none given)

Materials Restrictions

(none)

Thin Film and Materials Characterization

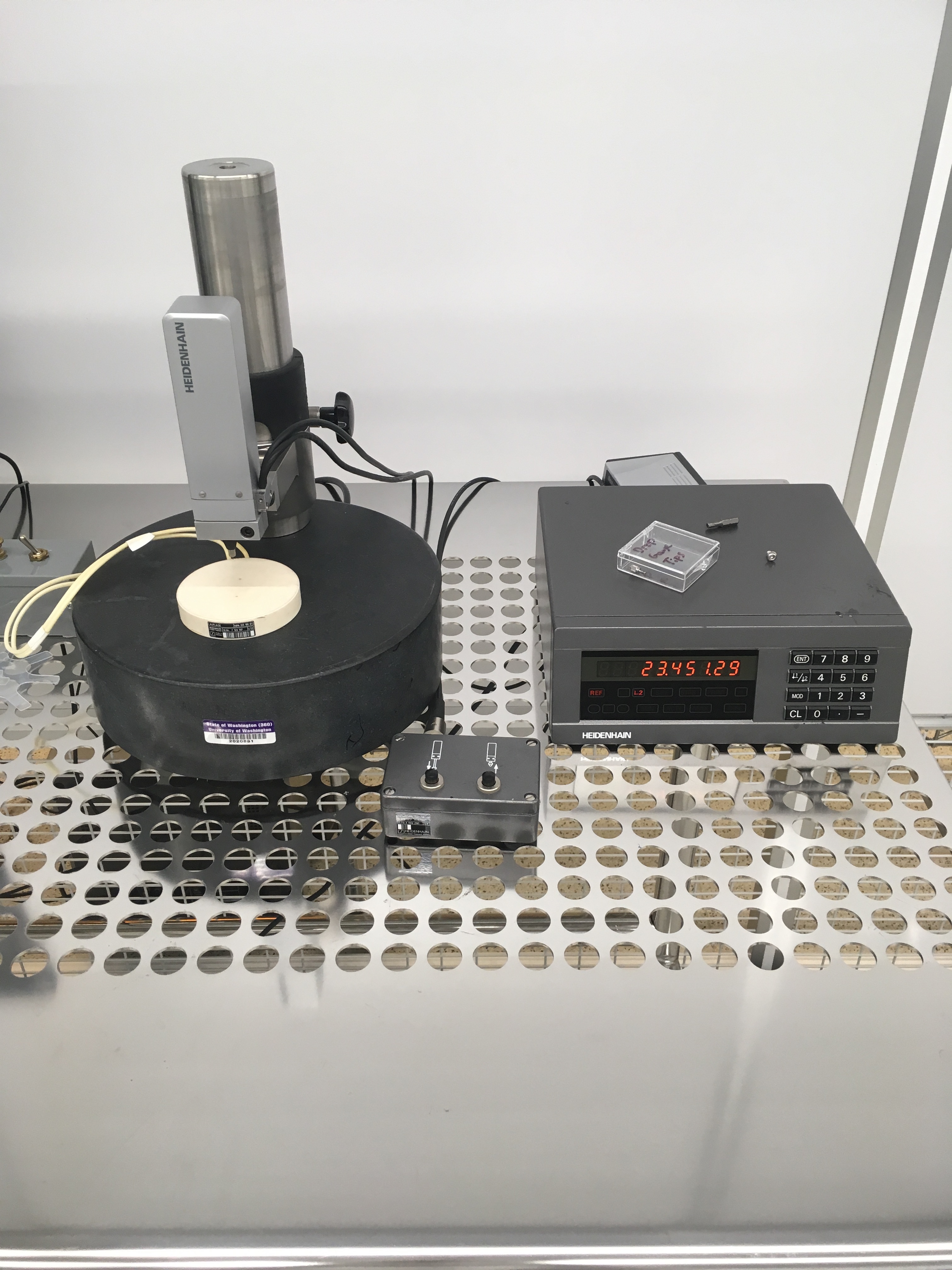

Drop Gauge |

| |

|---|---|---|

| Coral ID: | WNF--DropGauge | |

| Manufacturer: | HEIDENHAIN | |

| Model: | ND 281A | |

| Lab: | WNF | |

| Area: | Thin Film and Materials Characterization | |

| Manual: | DropGauge SOP 1.1.pdf | |

| UW Academic Rate: | $0/hr | |

| Industrial Rate: | $0/hr | |

| Outside Academic Rate: | $0/hr | |

Description

The drop gauge is a quick way to measure thickness of a sample. It has a range of 25 mm and an accuracy of 0.1 �m. The system consists of a measuring probe, a vacuum chuck, motion control box, and a numerical display box for measurement readout.

Details

(none given)

Materials Restrictions

- Ensure substrates are clean and dry

- The measurement probe will press into soft materials, causing inaccuracy in measurements and potentially damage to sensitive features. Choose measurement area accordingly.

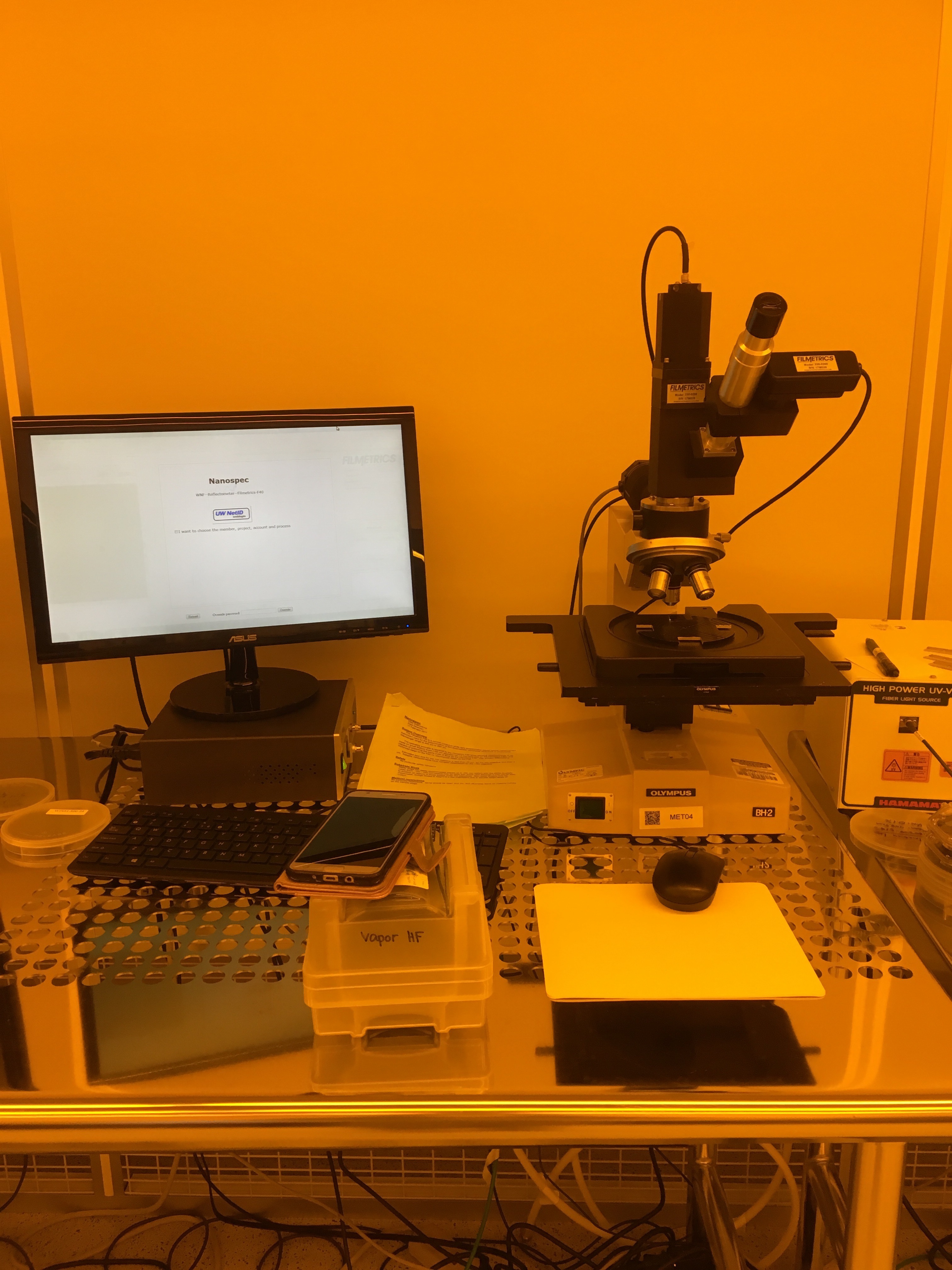

Filmetrics F40 Small Point Reflectometer |

| |

|---|---|---|

| Coral ID: | WNF--Reflectometer--Filmetrics-F40 | |

| Manufacturer: | Filmetrics | |

| Model: | 210 | |

| Lab: | WNF | |

| Area: | Thin Film and Materials Characterization | |

| Manual: | Nanospec SOP 20170216.pdf | |

| UW Academic Rate: | $11/hr | |

| Industrial Rate: | $33/hr | |

| Outside Academic Rate: | $11/hr | |

Description

Single-point spectral reflectance to measure film thickness and refractive index.

Details

(none given)

Materials Restrictions

(none)

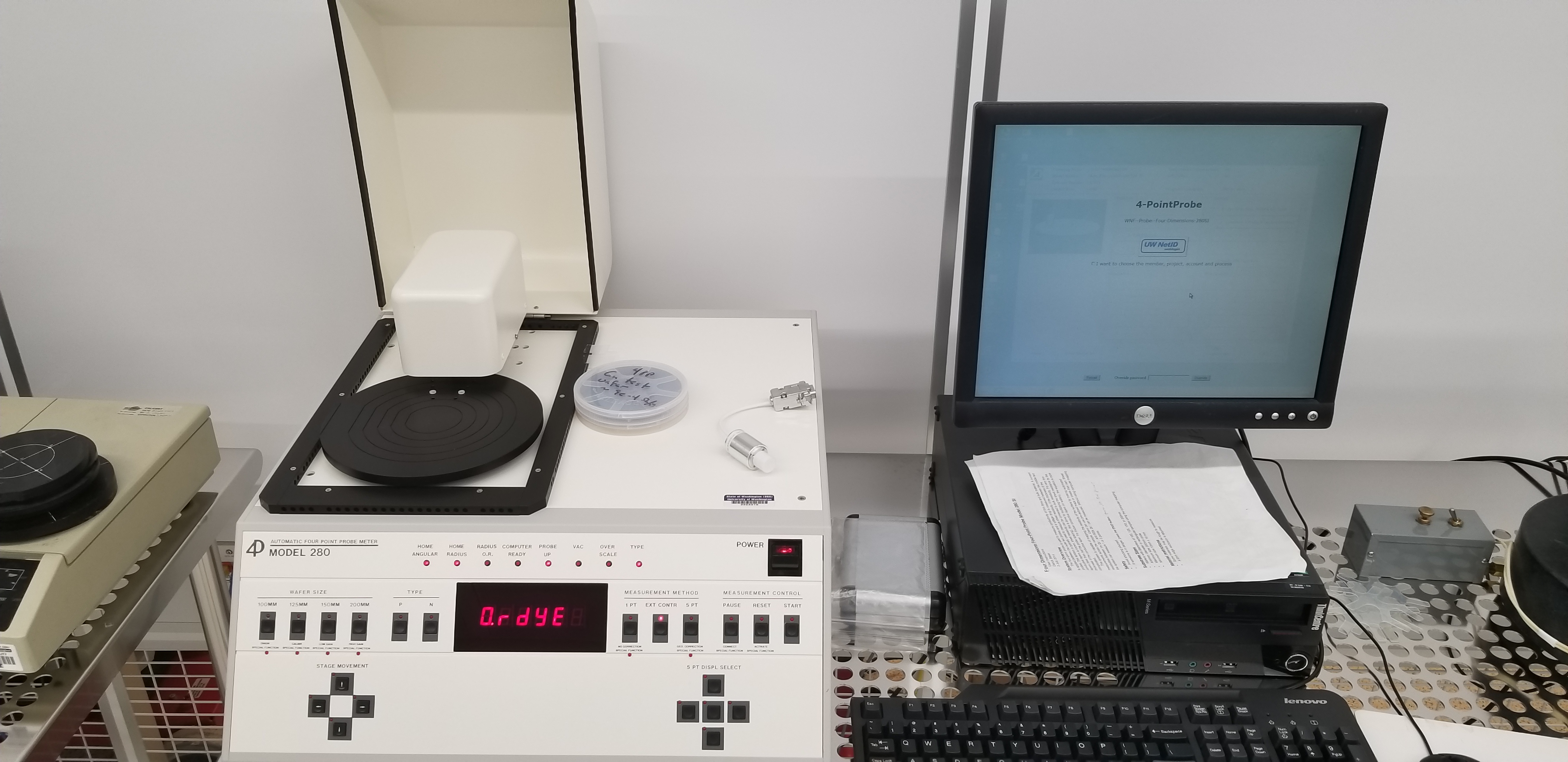

Four Dimensions Four-Point Probe Model 280 SI |

| |

|---|---|---|

| Coral ID: | WNF--Probe--Four-Dimensions-280SI | |

| Manufacturer: | Four Dimensions | |

| Model: | 280 SI | |

| Lab: | WNF | |

| Area: | Thin Film and Materials Characterization | |

| Manual: | Four-Point Probe SOP.pdf | |

| UW Academic Rate: | $0/hr | |

| Industrial Rate: | $0/hr | |

| Outside Academic Rate: | $0/hr | |

Description

The Four Dimensions Four-Point Probe Model 280 SI is capable for making sheet resistivity measurements on various samples. It can map the sheet resistance of samples up to 8 inches in diameter. There are standard maps in the system and custom maps can be created.

Details

The four-point probe is used to measure conductivity of thin films and bulk material. A current is applied between the outer two probes and a voltage drop is measured between the middle two probes. This system is typically used to measure sheet resistivity, if the thickness of the conductive layers is known, sheet resistivity can be converted to bulk resistivity

Materials Restrictions

Make sure samples are dry and clean before loading them into the four-point probe. For samples thicker than a wafer, make sure the probe head will clear the sample.

Thin Film Processing

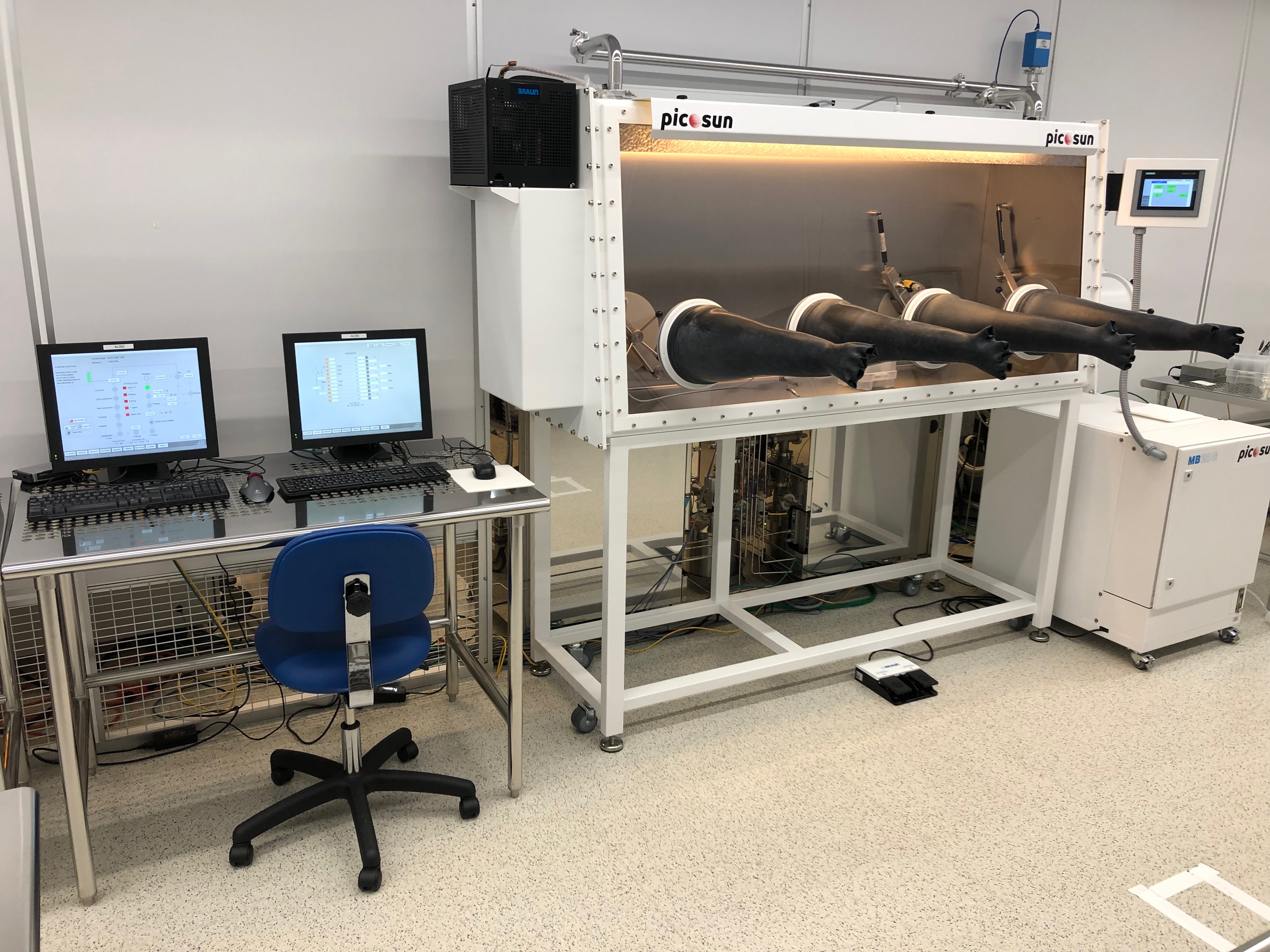

ALD chamber |

| |

|---|---|---|

| Coral ID: | WNF--ALD03--Picosun-R200 | |

| Manufacturer: | Picosun | |

| Model: | R200 | |

| Lab: | WNF | |

| Area: | Thin Film Processing | |

| Manual: | ALD02 and ALD03 SOP 20251202.pdf | |

| UW Academic Rate: | $33/hr | |

| Industrial Rate: | $99/hr | |

| Outside Academic Rate: | $33/hr | |

Description

Picosun tool number 400310

Details

Existing processes: Al2O3, Pt, TiO2

Other processes available on request: Ru

Chips, 1 to 25 100mm wafers, 1 to 6 150mm wafers, or single 200mm wafer per run.

Me3(MeCp)Pt or (3M)MCPt - trimethyl(methylcyclopentadienyl) platinum

(EtCp)2Ru or (EC)2Ru - bis(ethylcyclopentadienyl) ruthenium

TDMAT - tetrakis(dimethylamino) titanium

TMA - trimethyl aluminum

TiCl4 - titanium tetrachloride

Materials Restrictions

(none)

ALD chamber |

| |

|---|---|---|

| Coral ID: | WNF--ALD02--Picosun-R200 | |

| Manufacturer: | Picosun | |

| Model: | R200 | |

| Lab: | WNF | |

| Area: | Thin Film Processing | |

| Manual: | ALD02 and ALD03 SOP 20251202.pdf | |

| UW Academic Rate: | $33/hr | |

| Industrial Rate: | $99/hr | |

| Outside Academic Rate: | $33/hr | |

Description

Picosun tool number 400309

Details

Existing processes: SiO2, HfO2, ZnO

Other processes available on request: ZrO2, Al2O3

Chips, 1 to 25 100mm wafers, 1 to 6 150mm wafers, or single 200mm wafer per run.

TDMACZ - tris(dimethylamino)cyclopentadienyl zirconium

BDEAS - bis(diethylamino)silane

TMA - trimethyl aluminum

TEMAH - tetrakis(ethylmethylamino) hafnium

DEZ - diethyl zinc

Materials Restrictions

(none)

E-beam evaporator | ||

|---|---|---|

| Coral ID: | WNF--EVAP4 | |

| Manufacturer: | Angstrom Engineering | |

| Lab: | WNF | |

| Area: | Thin Film Processing | |

| Manual: | EVAP4 SOP 20260202.pdf | |

| UW Academic Rate: | $33/hr | |

| Industrial Rate: | $99/hr | |

| Outside Academic Rate: | $33/hr | |

Description

EVAP4 is a load locked electron beam evaporator for deposition of films on single wafers and chips. There are 8 pockets in the hearth, which uses 25cc liners.

Details

Materials available in the tool are listed under Config/Status above. If you wish to deposit a material that is not presently indicated as present in the tool, or require a film stack not listed below, contact staff to arrange source installation or coordinate process development.

Processes:

Al, Al2O3, Ag, Au, Cr, Cu, Nb, SiO2, Ta, Ti

Cr/Au, Ti/Au

Materials Restrictions

(none)

E-beam Evaporator 1 |

| |

|---|---|---|

| Coral ID: | WNF--EVAP1 | |

| Manufacturer: | CHA | |

| Model: | SEC-600 | |

| Lab: | WNF | |

| Area: | Thin Film Processing | |

| Manual: | EVAP1 - SOP 20260101.pdf | |

| UW Academic Rate: | $77/hr | |

| Industrial Rate: | $231/hr | |

| Outside Academic Rate: | $77/hr | |

Description

EVAP1 is an electron beam evaporator for depositing metal films. It is cryopumped with a base pressure less than 2x10-6 Torr. The system holds 4 crucibles of metal, thus up to 4 metals can be subsequently deposited.

Details

The system has a capacity up to nine 100mm wafers in a planetary holder. Smaller pieces can be held by inserts. Typical evaporation sources are Ti, Au, Cr, Pt, Ag, Al, Pd, Cu, and Ni. Other sources are available. Precious metals (Au, Pt, and Pd) are charged by use. Users are welcome to request new materials and need to work with staff on developing proper recipes. The distance from the evaporation source to the wafer holder is about 19.5 inches.

Serial Number: 11199

Gold, palladium, and platinum must be checked out in Coral weighed before and after use. A scale for this is available next to the checkout cabinet. Make sure the gold crucible is placed on two carbon disks. The platinum crucible must make very good thermal contact with the hearth to avoid melting. Make sure the crucible fits all the way into the hearth with the top of the crucible flush with the hearth, and that the hearth is very clean before it is loaded.

Materials Restrictions

Only pure metals are recommended. The evaporation process typically does not allow for effective deposition of compound materials. Photoresist-coated substrates are allowed. Inorganic substrates are allowed in the system. Organic substrates may be allowed with staff permission.

E-beam Evaporator 2 |

| |

|---|---|---|

| Coral ID: | WNF--EVAP2 | |

| Manufacturer: | CHA | |

| Model: | Solution | |

| Lab: | WNF | |

| Area: | Thin Film Processing | |

| Manual: | EVAP2 - SOP 20260101.pdf | |

| UW Academic Rate: | $77/hr | |

| Industrial Rate: | $231/hr | |

| Outside Academic Rate: | $77/hr | |

Description

The E-beam Evaporator is a metal evaporation system that uses an electron beam to heat the metal sources. The system has 6 pockets for different materials during deposition.

Pocket #1 is titanium, pocket #2 is chrome, Pocket #3 is gold, pocket #4 is platinum, pocked #5 is copper, molybdenum, palladium or silver, and pocket #6 is aluminum.

The materials are put into crucible liners for better heat uniformity throughout the source material and to allow for easy removal and refilling. The vacuum system is produced via a cryopump as the high vacuum pump. There is a mechanical pump that is capable of roughing the chamber and regenerating the cryopump as needed.

Details

This system has a capacity of up to seven 100mm wafers when using the liftoff fixturing and fifteen 100mm wafers when using the planetary. It can also hold 3 200mm wafers in a planetary configuration. Holders for smaller pieces are also available. This system is the most automated of our evaporation systems and is capable of producing multilayer stacks without user intervention. Precious metals (Au, Pd, and Pt) are charged by use. This system also includes a heater so that depositions can be performed at up to 300 C and an ion mill to clean surfaces prior to deposition. The distance from the evaporation source to the wafer holder is about 14.5 inches.

System #6629 Solution

Make sure the gold crucible is placed on two carbon disks. The platinum crucible must make very good thermal contact with the hearth to avoid melting. Make sure the crucible fits all the way into the hearth with the top of the crucible flush with the hearth, and that the hearth is very clean before it is loaded.

Materials Restrictions

Most substrates are allowed. Consult a staff member prior to new processes on substrates other than glass, quartz, or silicon. Only pure metals are recommended. The evaporation process typically does not allow for effective deposition of compound materials. Photoresist is typically allowed, but ask a staff member prior to performing a new process.

Evatec LLS EVO Sputter System |

| |

|---|---|---|

| Coral ID: | WNF--SPUT02 | |

| Manufacturer: | Evatec | |

| Model: | LLS EVO | |

| Lab: | WNF | |

| Area: | Thin Film Processing | |

| Manual: | SPUT01 SPUT02 SOP.pdf | |

| UW Academic Rate: | $77/hr | |

| Industrial Rate: | $231/hr | |

| Outside Academic Rate: | $77/hr | |

Description

This turbo pumped system with a cryo pumped load lock is used for batch sputter deposition of films.

Details

Up to ten wafers can be loaded into the system and deposited at the same time. Wafers are loaded vertically on panels and the system sputters horizontally. The system is plumbed with nitrogen and oxygen for reactive sputtering. The system can be setup for co-sputtering. The tool has a heater and an RF sputter etcher in the load lock.

Materials Restrictions

(none)

Evatec LLS EVO Sputter System |

| |

|---|---|---|

| Coral ID: | WNF--SPUT01 | |

| Manufacturer: | Evatec | |

| Model: | LLS EVO | |

| Lab: | WNF | |

| Area: | Thin Film Processing | |

| Manual: | SPUT01 SPUT02 SOP.pdf | |

| UW Academic Rate: | $77/hr | |

| Industrial Rate: | $231/hr | |

| Outside Academic Rate: | $77/hr | |

Description

This turbo pumped system with a cryo pumped load lock is used for batch sputter deposition of films.

Details

Twelve wafers up to 6" diameter can be loaded into the system and deposited at the same time. Wafers are loaded vertically on panels and the system sputters horizontally. The system is plumbed with nitrogen and oxygen for reactive sputtering. The system can be setup for co-sputtering. The tool has a heater and an RF sputter etcher in the load lock.

Materials Restrictions

(none)

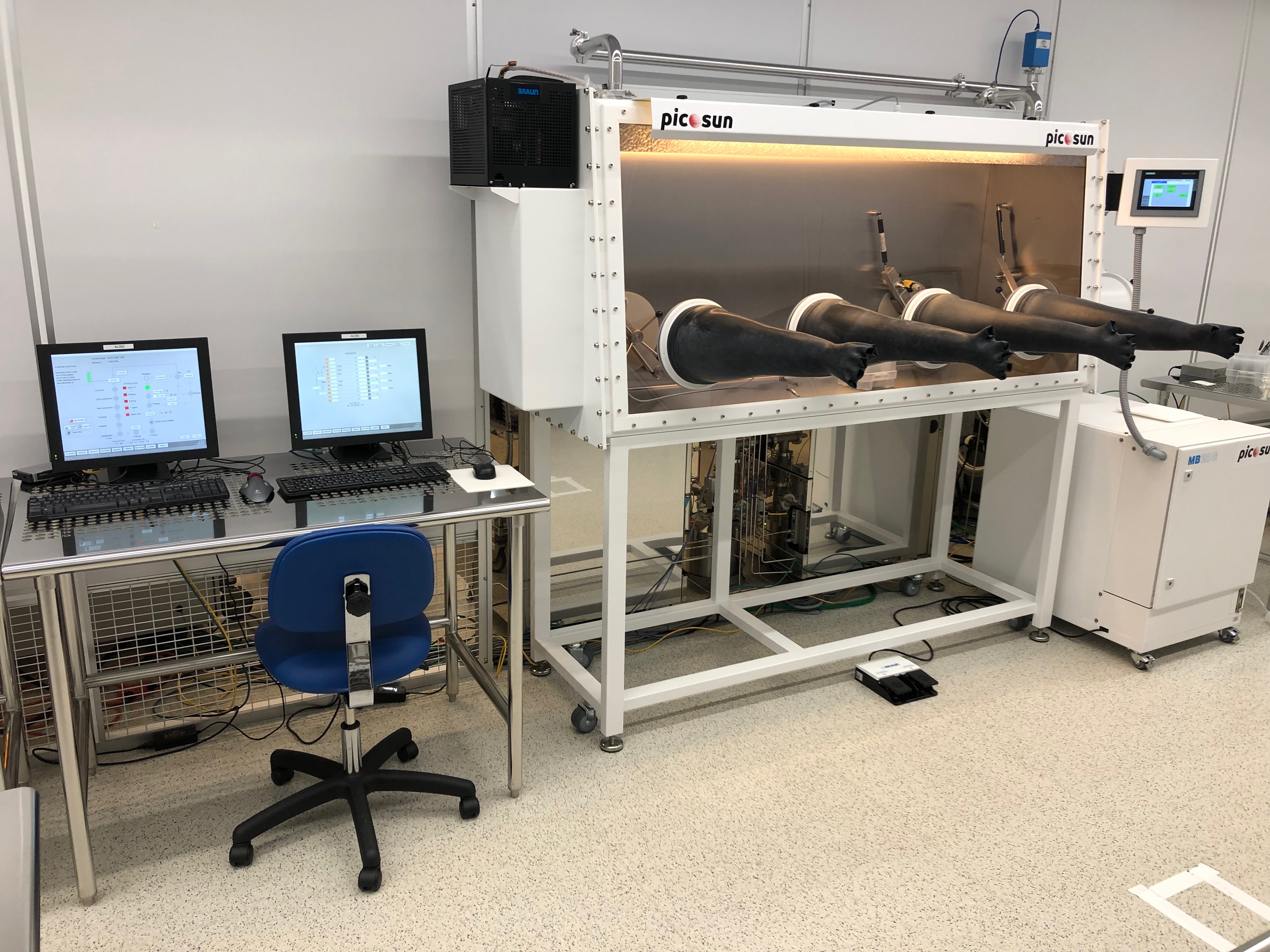

Expertech CTR200 Anneal Furnace |

| |

|---|---|---|

| Coral ID: | WNF--Furnace--Anneal | |

| Manufacturer: | Expertech | |

| Model: | CTR200 | |

| Lab: | WNF | |

| Area: | Thin Film Processing | |

| Manual: | Atmospheric Furnace SOP 20180828.pdf | |

| UW Academic Rate: | $11/hr | |

| Industrial Rate: | $33/hr | |

| Outside Academic Rate: | $11/hr | |

Description

This atmospheric tube furnace is capable of both dry oxidation and annealing.

Details

This anneal furnace has a maximum temperature of 1000C. It is plumbed with nitrogen, oxygen, and forming gas (2% H2 in N2). It can accommodate 44 wafers with diameters up to 200 mm. Irregular samples can be arranged with staff.

Materials Restrictions

This furnace does allow wafers contaminated with metals. Materials must be robust at the maximum temperature called for in the recipe.

Expertech CTR200 Oxidation Furnace |

| |

|---|---|---|

| Coral ID: | WNF--Furnace--Oxidation | |

| Manufacturer: | Expertech | |

| Model: | CTR200 | |

| Lab: | WNF | |

| Area: | Thin Film Processing | |

| Manual: | Atmospheric Furnace SOP 20180828.pdf | |

| UW Academic Rate: | $11/hr | |

| Industrial Rate: | $33/hr | |

| Outside Academic Rate: | $11/hr | |

Description

This atmospheric tube furnace is capable of both wet and dry oxidation.

Details

It has a maximum temperature of 1000C. It is plumbed with nitrogen, oxygen, and steam from a deionized water bubbler. It can accommodate 44 wafers with diameters up to 200 mm. Irregular samples can be arranged with staff.

Materials Restrictions

This furnace does not allow any metal-contaminated wafers. Wafers must be clean before oxidation.

Lesker Sputter |

| |

|---|---|---|

| Coral ID: | WNF--SPUT03--Lesker | |

| Manufacturer: | Lesker | |

| Model: | Lab 18 | |

| Lab: | WNF | |

| Area: | Thin Film Processing | |

| Manual: | SPUT03 Lesker Sputter - SOP.pdf | |

| UW Academic Rate: | $77/hr | |

| Industrial Rate: | $231/hr | |

| Outside Academic Rate: | $77/hr | |

Description

This cryo pumped system is used for sputter deposition of films, with DC, RF, and pulsed DC power supplies. Targets materials include: Al, Ti, Au, Ti/W, Ni, ZnO, ITO, Nb, Cr, Cu, Ir, and Ni/Cr.

Details

Three sample holders are available for the system. There are holders for both 150mm and 4 inch wafers, plus a reconfigurable small-parts holder. Small parts must be of similar thickness to a wafer. Additional holders for specific samples can be fabricated.

The system has four power supplies. Power supply 1 (1500W max, DC) can be connected to guns 1, 2, 3, and 4. Power supply 4 (600W max, RF) can be connected to all five guns. Power supply 5 (1500W max, DC/pulsed DC) connects only to gun 5. Power supply 6 (100W max, RF) is used to bias the substrate. Only one power supply can connected to each gun at one time. Up to three guns can be sputtering at the same time if the guns are chosen carefully e.g. Gun 1 (DC), Gun 3 (RF), Gun 5 (DC) could be used for cosputtering.

Radio frequency (RF) supplies are used to counteract charge buildup that occurs on nonconducting targets. This is required for most oxides and nitrides used in the system. Conductive samples can be sputtered using an RF supply, but tend to sputter more slowly than with DC supplies.

Materials Restrictions

Organic substrates require staff review and permission prior to use. Photoresists are allowed in the system. Target placement must be reserved in advance by contacting darick@uw.edu. The target schedule is available here: http://goo.gl/fd0Gbh

Pulse Power Supply |

| |

|---|---|---|

| Coral ID: | WNF--PPS | |

| Manufacturer: | Dynatronix | |

| Lab: | WNF | |

| Area: | Thin Film Processing | |

| Manual: | Pulse Power Suppy 20250116.pdf | |

| UW Academic Rate: | $11/hr | |

| Industrial Rate: | $33/hr | |

| Outside Academic Rate: | $11/hr | |

Description

Pulsed power supply for general electrodeposition processes.

This unit had originally been located in HOOD08 but was moved to HOOD10 when the GoldBath power supply failed.

Since HOOD08 has no designated power supply the electrode leads for the PPS must be plugged to the banana cable receptacles in HOOD10.

Details

(none given)

Materials Restrictions

(none)

Rapid Thermal Annealer |  (2).JPG)

| |

|---|---|---|

| Coral ID: | WNF--RTA-Clean | |

| Manufacturer: | Allwin32 | |

| Model: | AccuThermo AW 610 | |

| Lab: | WNF | |

| Area: | Thin Film Processing | |

| Manual: | RTA SOP 20171023.pdf | |

| UW Academic Rate: | $55/hr | |

| Industrial Rate: | $165/hr | |

| Outside Academic Rate: | $55/hr | |

Description

Rapid thermal annealer

Details

Clean system isolation tube: 1119-16518 Clean system quartz tray: 1119-16534 General system isolation tube 1117-15748 General system quartz tray: 1210-13236 Backup set isolation tube: 819-16467 Backup set quartz tray: 1119-16531

Materials Restrictions

(none)

SCS Labcoter Parylene Deposition System |

| |

|---|---|---|

| Coral ID: | WNF--Parylene | |

| Manufacturer: | SCS | |

| Model: | Labcoter | |

| Lab: | WNF | |

| Area: | Thin Film Processing | |

| Manual: | Parylene Coater SOP 20250103.pdf | |

| UW Academic Rate: | $33/hr | |

| Industrial Rate: | $99/hr | |

| Outside Academic Rate: | $33/hr | |

Description

The Labcoter is a parylene coating system used to cover samples with a conformal layer of parylene-c.

Details

(none given)

Materials Restrictions

(none)

SPTS PECVD |

| |

|---|---|---|

| Coral ID: | WNF--PECVD2-SPTS | |

| Manufacturer: | SPTS | |

| Model: | SPM | |

| Lab: | WNF | |

| Area: | Thin Film Processing | |

| Manual: | PECVD2 SOP 20260202.pdf | |

| UW Academic Rate: | $55/hr | |

| Industrial Rate: | $165/hr | |

| Outside Academic Rate: | $55/hr | |

Description

Low temperature (125C) and high temperature (350C), high-rate PECVD of SiO, SiN, and amorphous-Si on up to 200mm substrates with dual frequency supplies for stress tuning.

Details

This system runs automated depositions by first conditioning the chamber, then running the deposition, and then cleaning. This makes the deposited films very repeatable and minimizes the need for systems shutdowns to clean the chamber.

Materials Restrictions

Because the system runs at high temperatures it is imperative that samples be compatible with those temperatures. Prior to deposition on low temperature materials or plastics, consult with staff.

Wet Etch and Cleaning

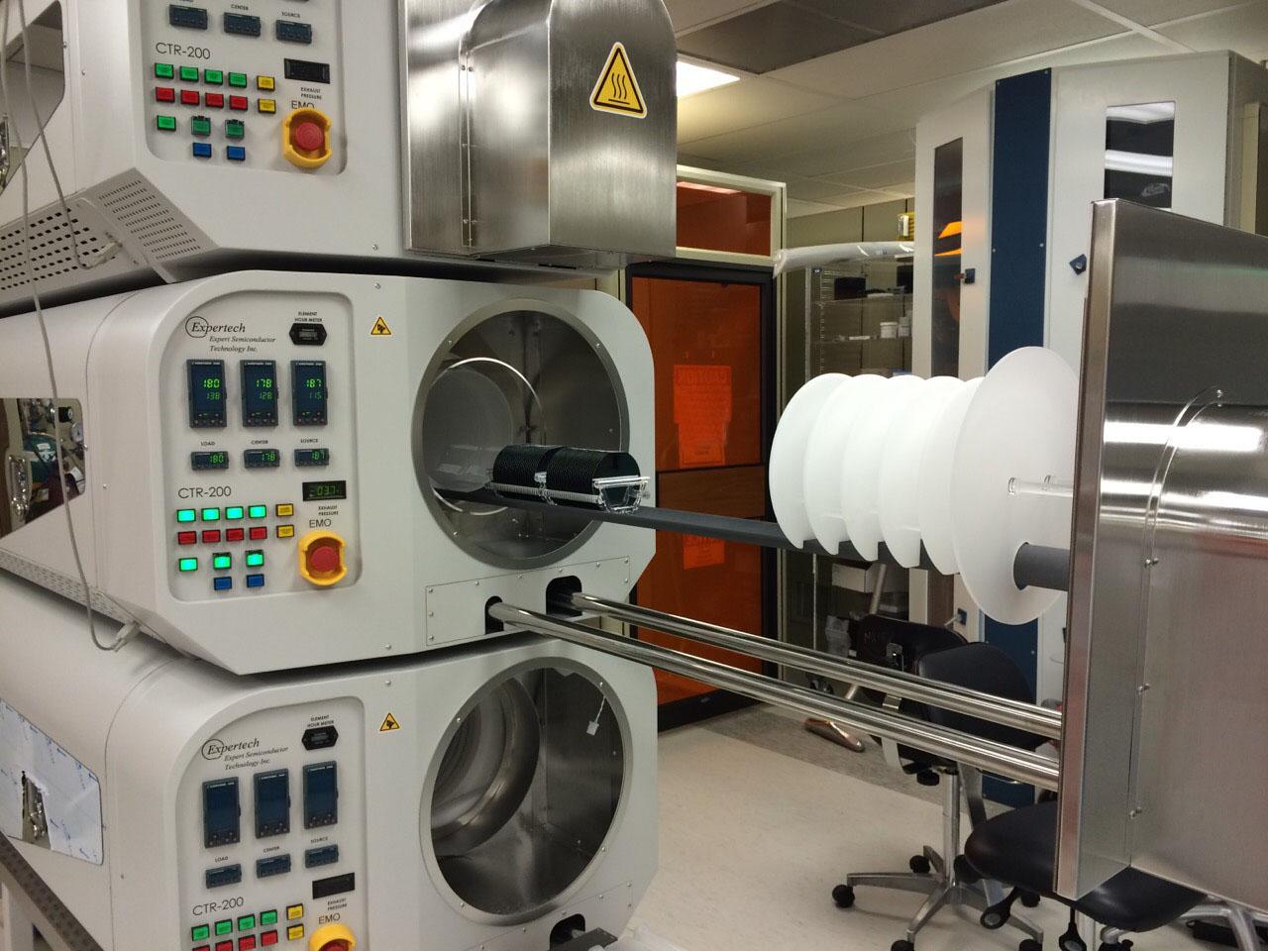

Critical Point Dryer |

| |

|---|---|---|

| Coral ID: | WNF--CPD01-Tousimis | |

| Manufacturer: | Tousimis | |

| Model: | 931 | |

| Lab: | WNF | |

| Area: | Wet Etch and Cleaning | |

| Manual: | CPD_SOP_Feb2025.pdf | |

| UW Academic Rate: | $11/hr | |

| Industrial Rate: | $33/hr | |

| Outside Academic Rate: | $11/hr | |

Description

The Tousimis Critical Point Dryer (CPD) uses liquid carbon dioxide (LCO2) to dry and release fragile parts without damaging the structure due to surface tension.

Details

(none given)

Materials Restrictions

(none)

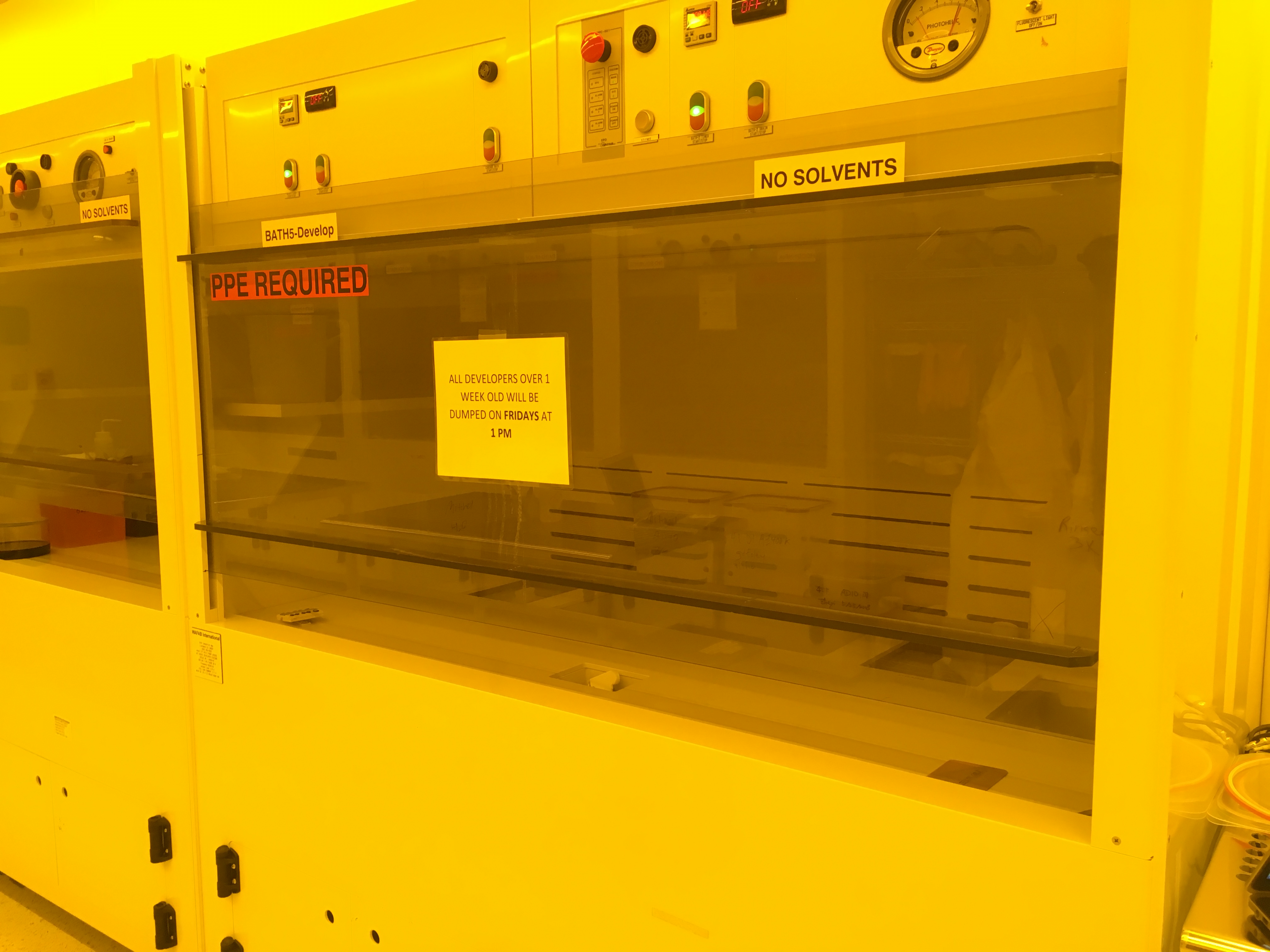

Developer Station |

| |

|---|---|---|

| Coral ID: | WNF--BATH5-Develop | |

| Manufacturer: | WAFAB International | |

| Model: | 72" PVC-C Front Access Wet Bench (Developer Station) | |

| Lab: | WNF | |

| Area: | Wet Etch and Cleaning | |

| Manual: | BATH5-Develop_3.0.pdf | |

Description

Wet bench with dedicated baths for photoresist developers

Details

(none given)

Materials Restrictions

(none)

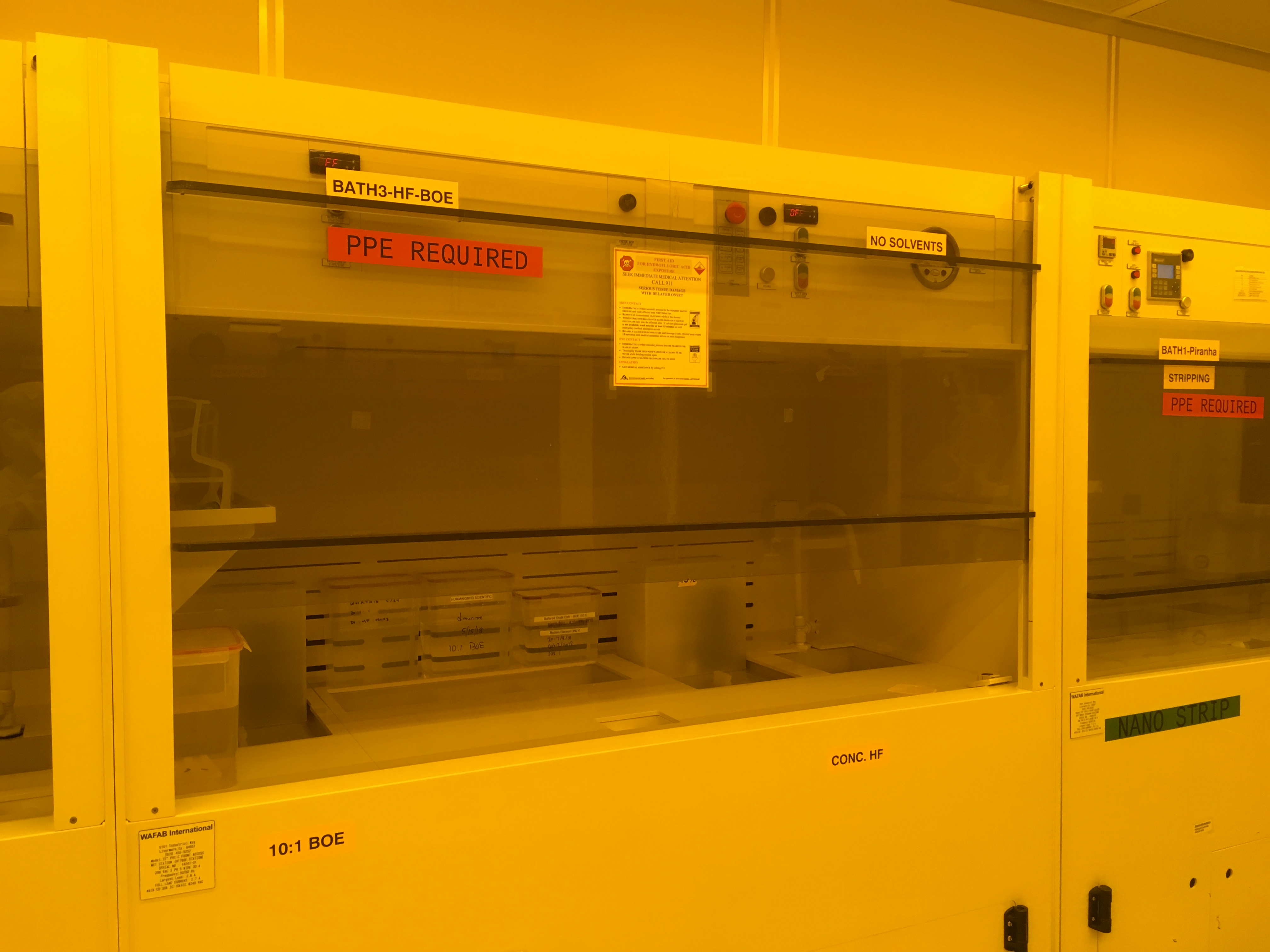

HF and BOE process station |

| |

|---|---|---|

| Coral ID: | WNF--BATH3-HF-BOE | |

| Manufacturer: | WAFAB International | |

| Model: | 72" PVC-C Front Access Wet Station (HF/BOE Station) | |

| Lab: | WNF | |

| Area: | Wet Etch and Cleaning | |

| Manual: | BATH3-HF-BOE_3.0.pdf | |

| UW Academic Rate: | $0/hr | |

| Industrial Rate: | $0/hr | |

| Outside Academic Rate: | $0/hr | |

Description

Wet bench dedicated to processing with HF containing materials.

Details

Refilled by request

Materials Restrictions

(none)

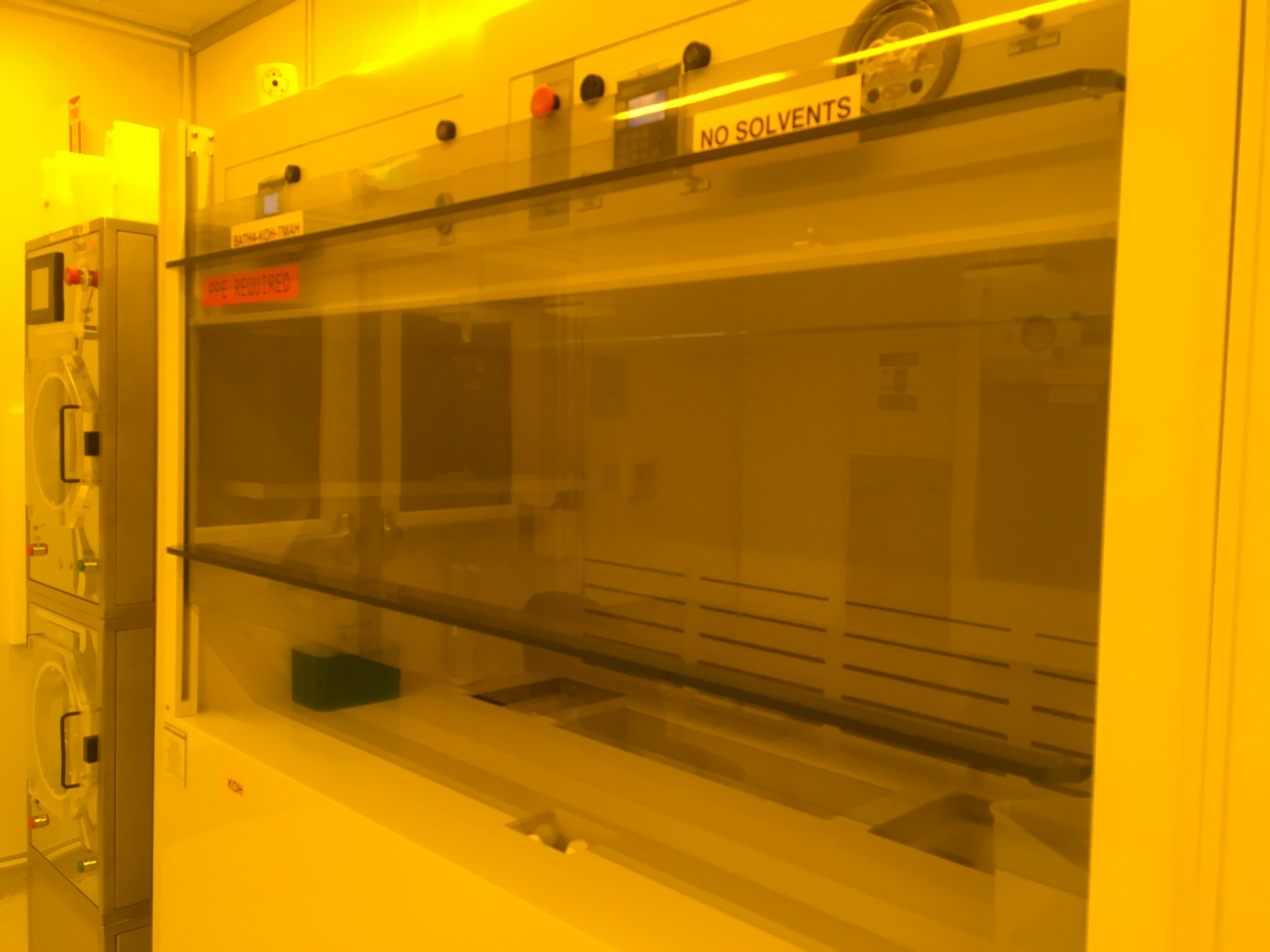

KOH-TMAH Station |

| |

|---|---|---|

| Coral ID: | WNF--BATH4-KOH-TMAH | |

| Manufacturer: | WAFAB International | |

| Model: | 72" Front Access Wet Bench (KOH/TMAH Station) | |

| Lab: | WNF | |

| Area: | Wet Etch and Cleaning | |

| Manual: | KOH_TMAH_Sept2022.pdf | |

Description

Wet bench with dedicated baths that can be used for KOH and TMAH.

Details

Both baths KOH. Please contact staff if TMAH processing is needed. Baths can be refilled by request

Materials Restrictions

(none)

Piranha Wet Bench |

| |

|---|---|---|

| Coral ID: | WNF--BATH1-Piranha | |

| Manufacturer: | WAFAB International | |

| Model: | 72" PVC-C Front Access Wet Bench (Piranha Station) | |

| Lab: | WNF | |

| Area: | Wet Etch and Cleaning | |

| Manual: | BATH1-Piranha_2.0.pdf | |

Description

Wet bench with dedicated baths for piranha and Nanostrip

Details

Piranha changed monthly

Materials Restrictions

(none)

RCA Station: |

| |

|---|---|---|

| Coral ID: | WNF--BATH2-RCA | |

| Manufacturer: | WAFAB International | |

| Model: | 72" PVC-C Front Access Wet Bench (RCA Station) | |

| Lab: | WNF | |

| Area: | Wet Etch and Cleaning | |

| Manual: | BATH2_RCA_March2023.pdf | |

Description

Wet bench dedicated to RCA Standard Clean 1 (SC1) and Standard Clean 2 (SC2)

Details

Turn on Heaters to reach operating temperature of 80C. Be sure to turn off heaters after use.

Baths Refilled upon Request. See Lab Status for latest Date.

SC1 (5:1:1 H2O:NH4OH:H2O2) -- Recommended change weekly.

SC2 (5:1:1 H2O:HCl:H2O2) -- Recommended change monthly

Materials Restrictions

(none)

Spin Rinse Dryer | .jpg)

| |

|---|---|---|

| Coral ID: | WNF--SRD1-4in | |

| Manufacturer: | Class One Technology | |

| Model: | Avenger Ultra-Pure | |

| Lab: | WNF | |

| Area: | Wet Etch and Cleaning | |

| Manual: | SRD SOP.pdf | |

Description

4 inch Wafer Rinse / Dryer

Details

(none given)

Materials Restrictions

(none)

Spin Rinse Dryer | .jpg)

| |

|---|---|---|

| Coral ID: | WNF--SRD1-6in | |

| Manufacturer: | Class One Technology | |

| Model: | Avenger Ultra-Pure | |

| Lab: | WNF | |

| Area: | Wet Etch and Cleaning | |

| Manual: | SRD SOP.pdf | |

Description

6 inch Wafer Rinse / Dryer

Details

(none given)

Materials Restrictions

(none)